Terbaikmachinery offers premium rod mills designed for efficient material grinding in mineral processing operations. Our rod milling equipment ensures reliable performance and precise particle size reduction, enhancing material pulverization and ore grinding processes. Trust Terbaikmachinery for expertly crafted grinding solutions that deliver superior results and optimize productivity.

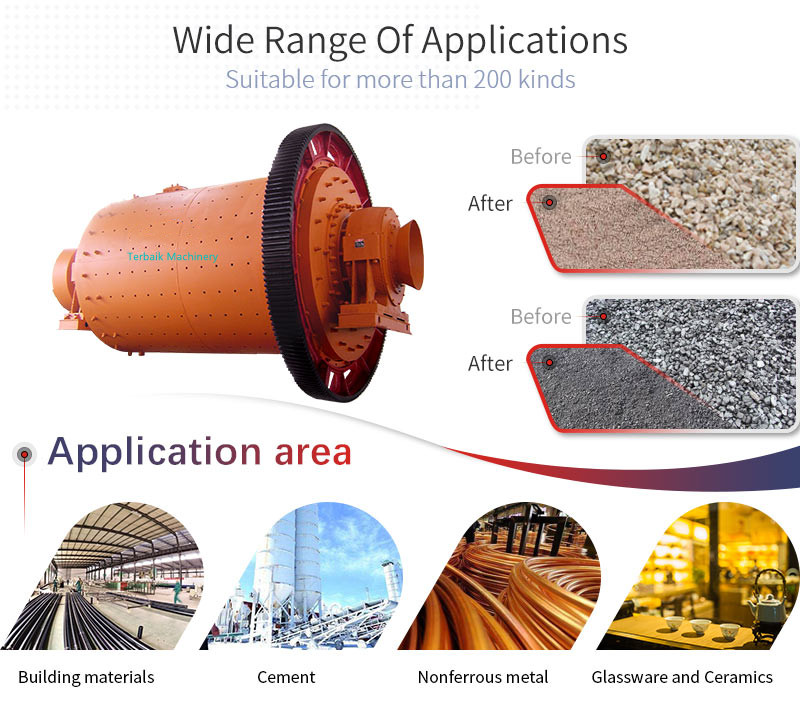

.Rod mill is a mill in which the grinding body loaded in the cylinder is a steel rod. Rod mills are generally of wet overflow type, which can be used as primary open-circuit grinding, and are widely used in primary grinding of artificial stone sand, sand making machine, mineral processing plants, and power departments of chemical plants.

In the grinding process, the grinding medium is in line contact with the ore, which has a certain selective grinding effect. The particle size of the product is relatively uniform, and there is less over-crushing. When used for rough grinding, the processing capacity of the rod mill is greater than that of the ball mill of the same specification.

It is widely used in the first-level grinding of artificial stone sand, mineral processing plants, chemical plants and electric power departments.

1. Feed evenly

Uniform feeding is an important operation to ensure the highest output and stable quality (fineness) of the rod mill.

The fineness of the product becomes thicker, which generally means that the feeding amount is too large;

The fineness of the product becomes thinner, which means that the feeding amount is less

According to this principle, adjust the feeding amount in time.

2. Add steel rods in time

If it is not added in time, the grinding capacity of the rod mill will decrease and the output will decrease.

1.When heavy separation or magnetic separation of tungsten tin ore and other rare metal ores, rod mills are often used to prevent excessive crushing;

2.In the second-stage grinding process, rod mills are generally used as the first-stage grinding equipment, which has larger production capacity and higher efficiency.

3.When processing softer or less hard ores, rod mills can be used to replace short-head cone crushers for fine crushing, which is not only simple in configuration, but also low in cost, and simplifies dust removal in the workshop.

High grinding efficiency: Older equipment saves more than 40% of power. The particle size of the product is more uniform, and there are fewer coarse particles and sludge. Compared with the particle size characteristics of the rod mill product and the ball mill product, the particle size characteristic curve of the rod mill in the open-circuit operation is almost the same as that of the ball mill in the closed-circuit operation.

Wide range of use: The use of high-quality controllable feeding and discharging rod mill technology, combined with the actual user’s grinding materials, is equipped with a suitable grinding body, which changes the surface contact of the traditional ball mill to line contact, so that the discharge particle size of the rod mill is more uniform and the output is higher. High, suitable for ores with different hardness (Mohs hardness 5.5~12).

Simple maintenance: The granularity of the discharging material can be changed by simple adjustment. The fineness control device is built-in, and the discharging device can be added with a screening device. The two checks ensure that neither over-grinding nor unqualified products are mixed into the finished product. The particle size characteristics of rod mill products are related to the ore crushed by rod mills. When the rod hits the ore, it first strikes the coarse particles, and then grinds the smaller ore particles, thereby reducing the risk of over-crushing. When the rod rotates and rises along the liner, the coarse particles are sandwiched in between, like a rod sieve, allowing fine particles to pass through the gap between the rods. This is also conducive to crushing the coarse particles and making the coarse particles concentrated in the grinding medium. The place to hit. Therefore, the rod mill product is more uniform, and the over-crushing is lighter.

High precision: Can achieve fine grinding of materials, and high precision of the grinding process.

1. Analysis of grinding media

The difference in grinding media is the main difference between the two

Rod mill: steel rods with a diameter of 50-100mm are used as grinding media, and the steel rods are in line contact e grinding m

Ball mill: steel balls are used as grinding media, and the steel balls are in point contact

The steel balls of the ball mill are in point contact, and the steel rods of the rod mill are in line contact, so the working characteristics of the two are obviously different.

2. Application

Ball mill are more than fine grinding, rod mill are mostly used for rough

Rod mill: Mainly used in rough grinding. When the product size is 1-3mm, the processing capacity of the rod mill is greater than that of the ball mill of the same specification.

Ball mill: When used for fine grinding and the product size is less than 0.5mm, the grinding effect of the ball mill is greater than that of the rod mill of the same specification.

3. Performance analysis

Rod mill: The process characteristic of the rod mill is that the product is coarser, but the particle size is uniform, contains less coarse particles and sludge, and is lighter over smashing.

Ball mill: The performance characteristics of the ball mill are high production capacity, strong adaptability to materials, high degree of fineness of materials, and fine discharge granularity.

4.Analysis of medium filling rate

The medium filling rate refers to the percentage of the grinding medium in the volume of the mill. For different grinding methods, mill structures, operating conditions and media shapes, the media filling rate has a suitable range, too high or too low will affect the grinding effect.

Ball mill: filling rate is 40%-50%

Rod mill is 35%-45%

The packing rate of the self-mill is 25%-40%, and the packing rate of the gravel mill is about 43%.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

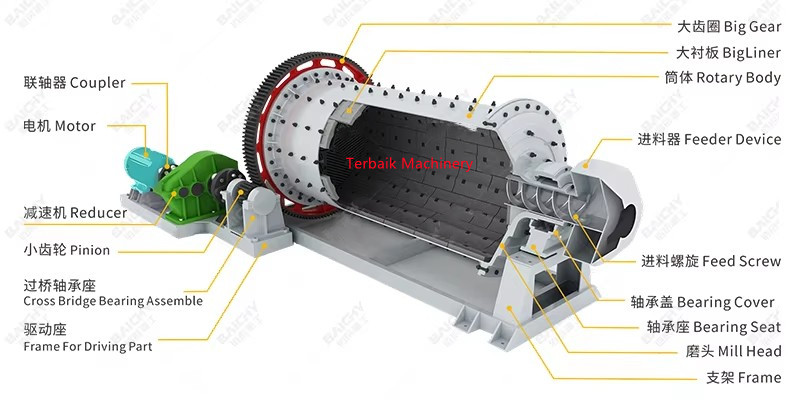

The rod mill operates on a principle similar to that of a ball mill but uses rods as the grinding medium. Here's a breakdown of its working principle:

1. Material Introduction and Rotation

The rod mill is driven by an outer gear mechanism. Materials are fed into the mill through a feeding device, which directs them into the rotating cylinder. Inside the mill, the cavity is lined with wear-resistant plates and filled with rods of various specifications.

2.Grinding process

As the cylinder rotates, centrifugal force causes the rods to rise to a certain height. When the rods fall back down, they impact and grind the material. This continuous action of rising and falling rods crushes the material to achieve the desired particle size.

3. Discharge of Ground Material

Once the material reaches the desired fineness, it is discharged through the mill's outlet port. This completes the grinding process, and the finely ground powder is collected for further use or processing.

The rod mill's design ensures effective grinding through a combination of impact and abrasion, making it suitable for various grinding applications.

The grinding drum liner is a protective layer covering the inner wall of the grinding drum of the ball mill to protect the grinding drum from wear and chemical corrosion of the grinding balls; it is usually made of wear-resistant and corrosion-resistant materials, such as high-chromium alloy steel, rubber or polyurethane.

Grinding balls are usually made of steel balls or ceramic balls, and their size and material selection are determined according to the hardness of the material and the grinding requirements. The general diameter is between 20-125mm, and the super-large ball mill can reach 130-150mm.

There are many kinds of accessories for ball mills, each of which carries specific functions and roles, which together ensure the normal operation and efficient grinding of the ball mill. When purchasing and using accessories, they should be reasonably selected and configured according to the specific model and operation requirements of the ball mill.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

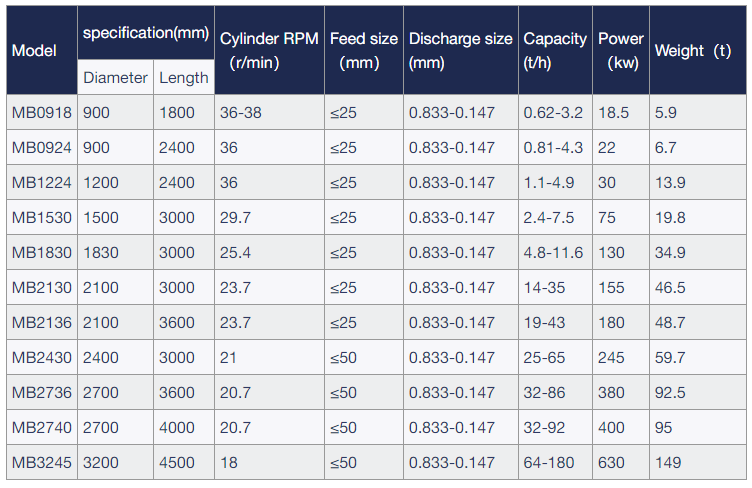

*The output will vary according to different materials, feed particle size and other factors