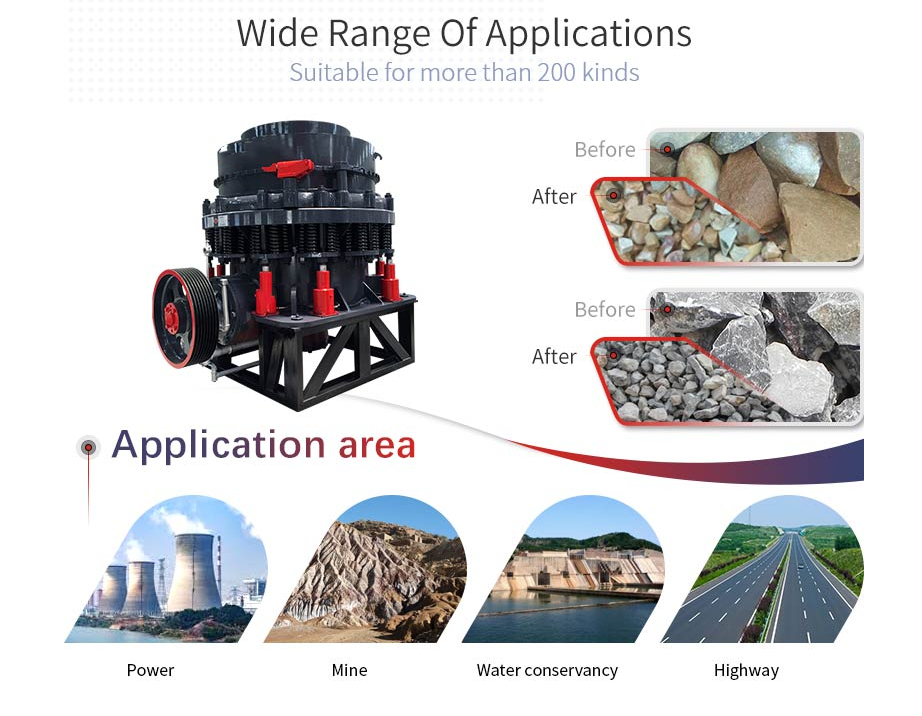

Terbaikmachinery offers Symons Cone Crushers for reliable crushing solutions in mining industries. Our Symons Cone Crushers ensure efficient material crushing, enhancing productivity and product quality.

Symons cone crusher has been developed to crush high or medium hardness material, such as iron ore , copper ore, limestone, quartz, granite, and sand stones, etc. And the nile cone crusher is used in metallurgical, construction, road building, chemical, silicate Industries. The cone crusher has the advantage of reliable construction, high prod activity, easy adjustment and less cost in operation.

Symons cone crusher is a high-performance cone crushing equipment designed and developed based on the principle of laminated crushing and the concept of more crushing and less grinding, based on the introduction and absorption of foreign technology, according to customer needs.

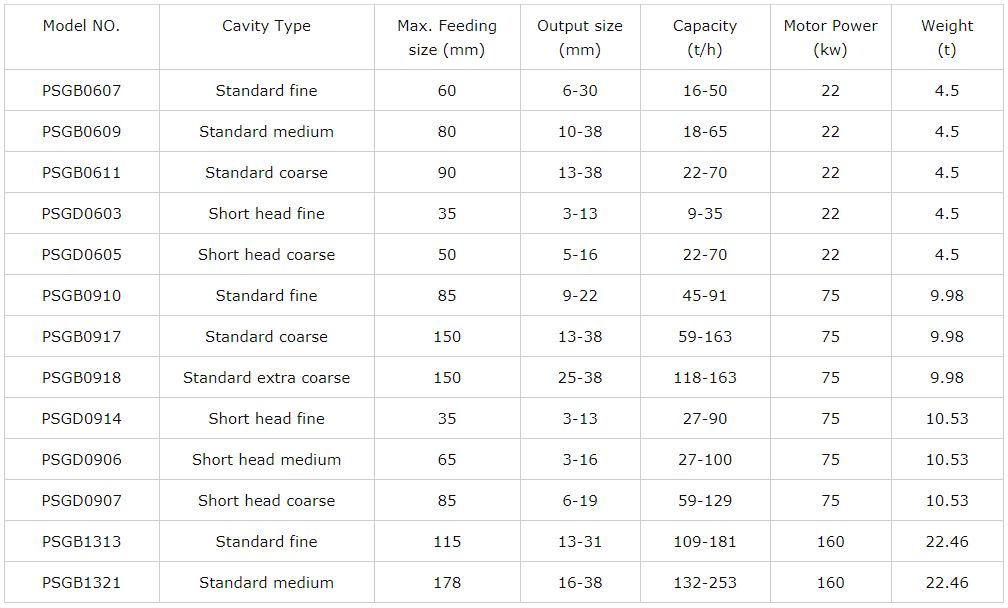

PSG series standard cone crushers usually handle materials of various hardness; short-head cone crushers are suitable for medium and fine crushing operations. Its crushing chamber design makes it more efficient when handling finer materials and has better product particle size; specific models include PSGB0607, PSGB0907, PSGB1324, etc.

1. Uniform product size: By adjusting the working parameters of the crusher, the product size can be precisely controlled, the circulating load can be reduced, and the production efficiency can be improved.

2. Thin oil lubrication system:The unique thin oil lubrication system design not only improves the service life of the equipment but also reduces the consumption and emission of lubricating oil, which is beneficial to environmental protection.

3. Overload protection device: The spring insurance system, can automatically increase the discharge port when the unbreakable object passes through the crushing chamber, discharge foreign matter, and resume work to prevent damage to the machine.

4. Wear-resistant material: The surface of the crushing chamber is paved with wear-resistant high manganese steel lining, which improves the wear resistance and service life of the equipment.

5. Multiple models are available: According to the different crushing principles and application fields, cone crushers can be divided into multiple models, and users can choose the appropriate equipment according to their actual needs.

1. As the most traditional cone crusher the spring cone crusher is the earliest model used in the market, with relatively low production capacity and high production cost.

2. Hydraulic cone crusher is further divided into three types: full hydraulic, single-bar hydraulic, and multi-cylinder hydraulic.

3. Single-bar hydraulic cone crusher integrates mechanical, hydraulic, and intelligent control in one crushing structure, with a relatively long service life, convenient replacement and maintenance, low failure rate, and high output.

4. Multi-cylinder hydraulic cone crusher increases the number of cylinders on the basis of a single-bar, which is more convenient to adjust and repair, with a relatively longer service life, better discharge quality, and lower cost.

5. A fully hydraulic cone crusher combines the advantages of a single-bar cone crusher and compound cone crusher, adopts specific crushing frequency and eccentricity, has a high content of medium fineness, high production efficiency, and low energy consumption.

6. Compound cone crusher is a type of cone crusher that combines multiple technical advantages.

7. Mobile cone crushers can be divided into spring cone crushers, single-cylinder cone crushers, multi-cylinder hydraulic cone crushers, full hydraulic cone crushers and other types according to the type of cone crusher carried. There are two types of mobile cone crushers: crawler type and head-pulled type, which are easy to move and transfer.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

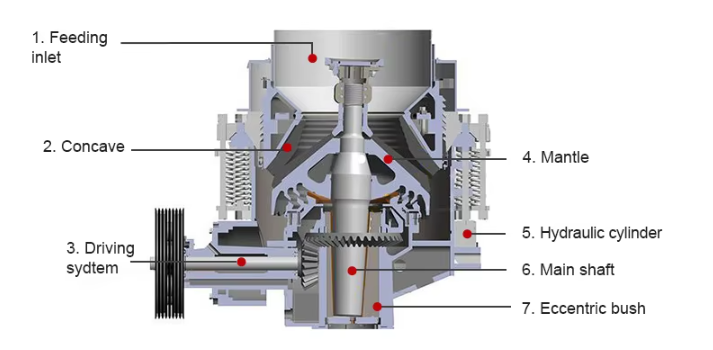

Core components: The symons cone crusher mainly comprises frame, cone (including dynamic cone and static cone), crushing wall, transmission device, crushing chamber, adjustment device, and other parts. Among them, the cone is the core part of the crusher, which is composed of a dynamic cone and a static cone.

Transmission mode: The motor transmits power to the cone part through a pulley or coupling, cone crusher transmission shaft and other devices. The cone part swings around a fixed point under the force of the eccentric sleeve.

Compression and crushing: The material is compressed by the cone and the wall in the cone-crushing chamber. The eccentric shaft of the cone makes the cone rotate in the crushing chamber, thereby generating pressure and impact force. The material is compressed, bent, and sheared between the dynamic cone and the static cone, thereby achieving the crushing effect. This lamination crushing method helps to form a more uniform particle size distribution.

Related:

What is the spare parts of Spring cone crusher ?

1. Mantle is Mn13Cr2 ,it can use 6-10 months ,we suggest you buy two sets as standby .

2. concave is Mn13Cr2 ,it can use 6-10 months ,we suggest you buy two sets as standby.

3.Bowl liner is copper ,it can use 12 months ,we suggest you buy one set as standby.

1. Mortar wall: As a key component of the cone crusher, the mortar wall and the crushing wall work together to squeeze and crush the material. It is usually made of wear-resistant materials, such as manganese steel.

2. Crushing wall: Corresponding to the mortar wall, the crushing wall is also a component in the cone crusher that directly participates in the crushing operation. It is fixed on the moving cone of the cone crusher and forms a crushing chamber with the mortar wall.

3. Fixed cone liner: The fixed cone liner is a fixed component in the cone crusher, which is used to support the mortar wall and protect the crusher body.

4. Moving cone liner: The moving cone liner is installed on the moving cone and rotates with the crushing wall to crush the material.

5. Bearing copper sleeve: The bearing copper sleeve in the cone crusher is used to support and fix key components such as the main shaft to ensure its normal operation.

About delivery standards

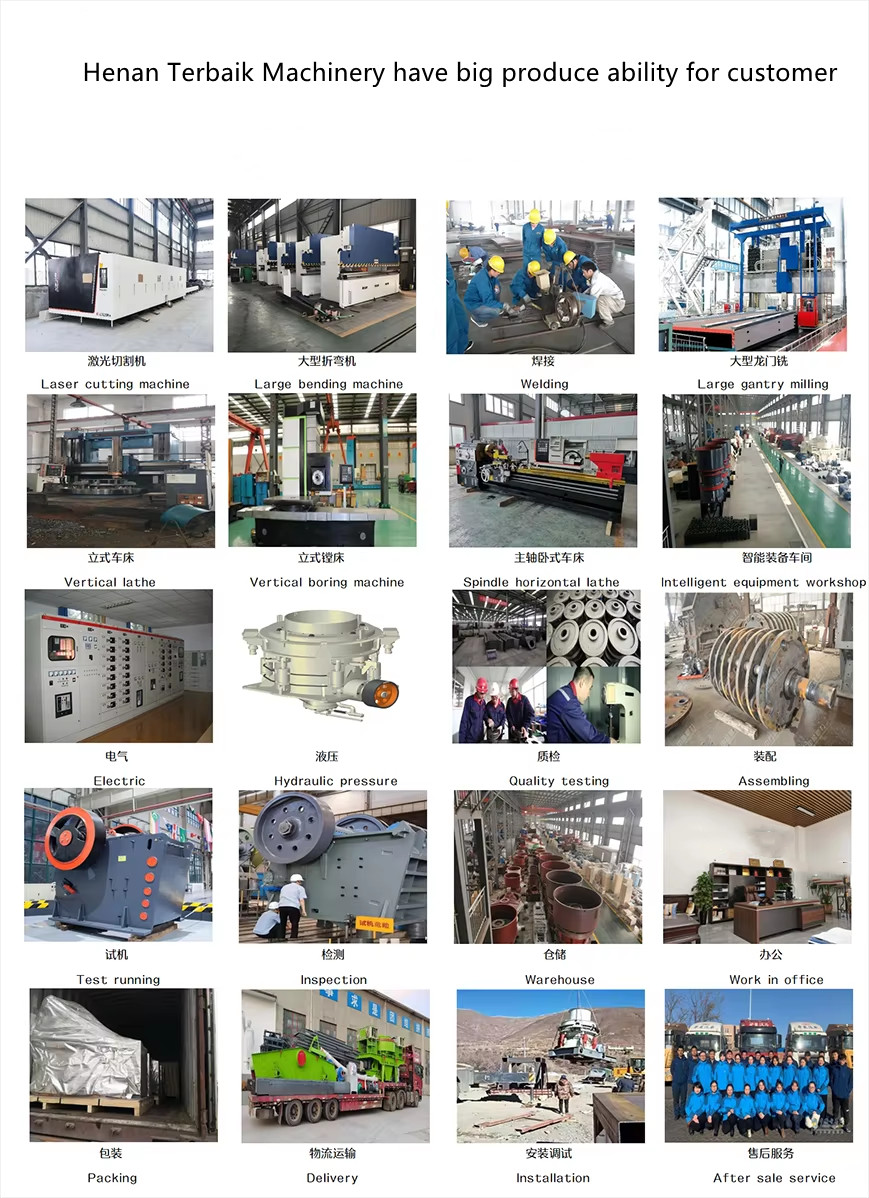

Terbaik machinery has extremely complete delivery standards, a series of standards and regulations formulated to ensure that the ordered goods can be delivered completely and accurately according to the needs and requirements of customers. These standards usually involve quantity, specifications, quality, packaging, documents and time, etc., to ensure the smooth progress of the delivery process and improve customer satisfaction.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors