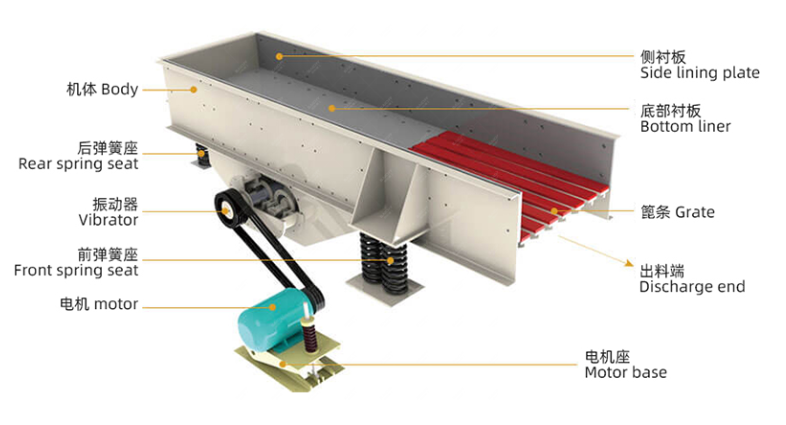

Terbaikmachinery's ZSW Series Vibrating Feeders offer reliable solutions for material feeding needs. With robust construction and precise control, our vibrating feeders ensure efficient and consistent feeding of materials, enhancing productivity in various industries. Trust Terbaikmachinery for expertly crafted vibrating feeders that deliver optimal performance and streamline your material handling processes.

Vibrating feeder can send massive and granular materials from storage bin to feeding device evenly, regularly and continuously, at the same time, realize coarse sieving of materials, so vibratory feeder is widely used in crushing or screening production line in metallurgy, coal mine, mineral dressing, building materials, chemical, abrasive material and other industries.

Electric Powered Vibro Capacity Vibratory Feeder for Mining Feeder Applications

1. Stable operation, reliable work, long service life, easy installation, convenient maintain and easy automatic control.

2. Adopt double-shaft vibrator and liner vibrator to finish the feeding and screening process at the same time.

3. Continuously and evenly feeding for rough crusher to proceed the coarse screening.

4. Can install the variable-frequency and variable-speed motor to regulate frequency, change the production, and control the feed quantity easily without starting frequently.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

What Is The Working Principle Of The Vibrating Feeder ?

The vibration exciter is composed of two eccentric shafts with particular position. The large linear vibration force produced by motor and the rotation of two eccentric shafts vibrates the machine. The materials are sliding and thrown so that they could move on. When the materials pass the screen bars, the small ore falls through the clearance of screen bars.frequently.

Related Products:

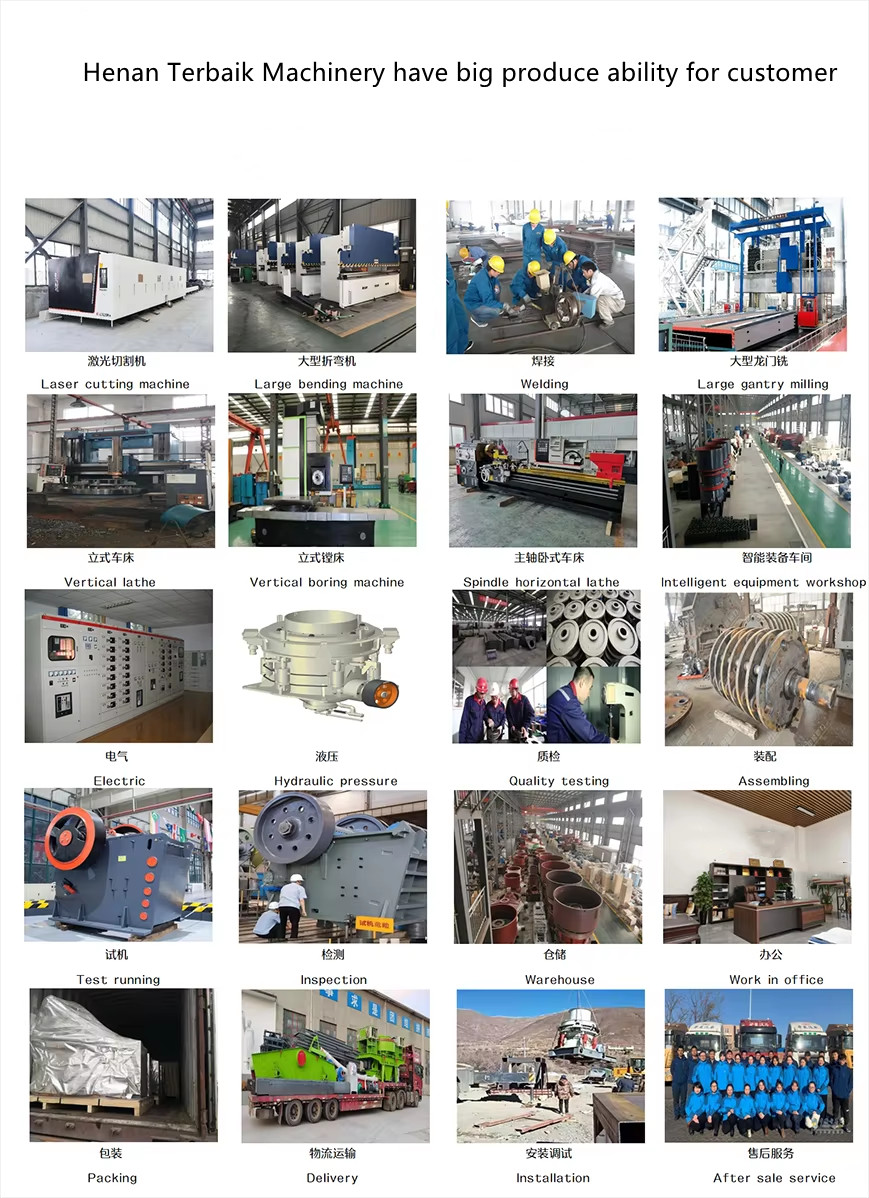

About delivery standards

Terbaik machinery has extremely complete delivery standards, a series of standards and regulations formulated to ensure that the ordered goods can be delivered completely and accurately according to the needs and requirements of customers. These standards usually involve quantity, specifications, quality, packaging, documents and time, etc., to ensure the smooth progress of the delivery process and improve customer satisfaction.

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

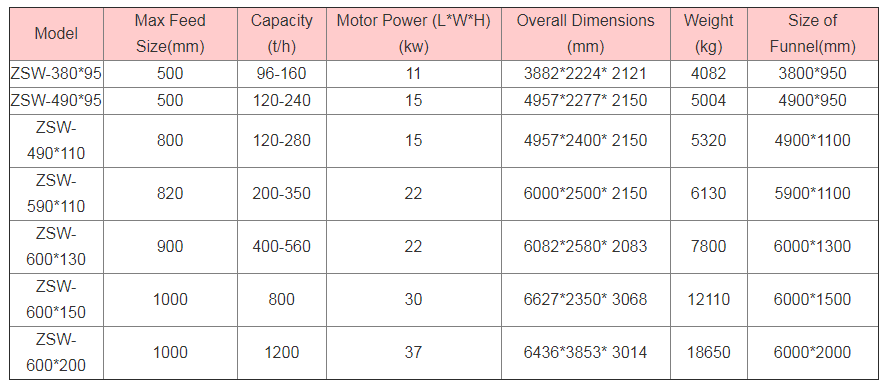

*The output will vary according to different materials, feed particle size and other factors