Terbaikmachinery offers high-quality rotary coolers designed to efficiently cool bulk materials in various industries. Our industrial-grade rotary cooling drums are engineered for optimal performance, providing reliable cooling solutions for a wide range of applications. Trust Terbaikmachinery for expertly crafted material cooling equipment that ensures consistent cooling performance and enhances productivity in your material processing operations.

Rotary Coolers in Processing:

Rotary coolers are essential components in the fertilizer industry, designed to cool granular materials efficiently after they have been dried or heated in a rotary drum dryer. They are crucial for reducing moisture content, stabilizing temperature, and improving the quality of the final product before storage or further processing.

Components of Rotary Coolers:

Drum Body: The main cylindrical vessel where materials are cooled. It is inclined slightly to facilitate the movement of materials through gravity.

Spiral Plate and Lifting Board: These components help in lifting and tumbling the materials inside the drum, ensuring thorough mixing and maximum exposure to cooling air.

Hopper: Receives the cooled materials and directs them towards the discharge point.

Cyclone Dust Catcher: Removes dust and fine particles from the cooling air to maintain environmental and operational cleanliness.

Cooling Pipe System: Channels chilled air or cool water around the drum to facilitate rapid heat exchange and cooling of the materials.

Applications of Rotary Coolers:

Rotary coolers are primarily used in the fertilizer industry to cool a variety of granular materials, including:

Fertilizers: After drying or chemical treatment, rotary coolers ensure uniform cooling and moisture reduction, improving fertilizer quality.

Pigments: Cooling pigments to prevent agglomeration and maintain product integrity.

Ultra-fine Materials: Cooling sensitive materials where maintaining a controlled environment is critical to prevent oxidation or degradation.

Additional Considerations:

Energy Efficiency: Utilizes indirect cooling methods like water deluge systems to reduce energy consumption and improve operational efficiency.

Maintenance and Support: Regular maintenance and support services ensure reliable operation and extend equipment lifespan.

In essence, rotary coolers are versatile machines crucial for maintaining product quality and optimizing processes in the fertilizer industry and beyond. Their design flexibility and efficiency make them indispensable for various material cooling applications.

Features and Advantages of Rotary Coolers:

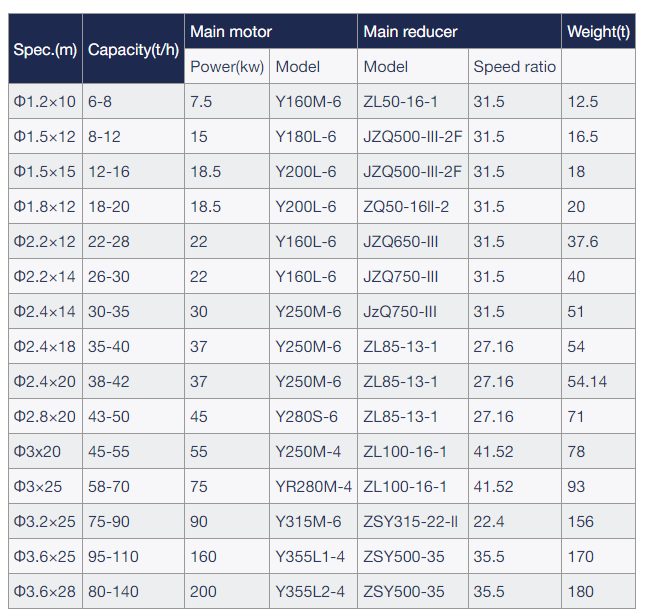

Custom Design: Tailored to specific production needs, including diameter, length, and material handling capacity.

Efficiency: Optimized design with custom flight arrangements and counter-current flow patterns to maximize cooling efficiency.

Durability: Constructed from durable materials such as carbon steel, stainless steel, or specialty alloys to withstand harsh operating conditions and prolong equipment life.

Automation Integration: Can be equipped with advanced automation controls for precise temperature monitoring, process control, and operational efficiency.

Environmental Compliance: Designed with cyclone dust catchers and other features to meet environmental regulations and minimize dust emissions.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Working Principle of Rotary Coolers:

Rotary coolers operate on the principle of tumbling materials inside a rotating drum while cooling air or water circulates around the drum's exterior. Here’s how it works:

Material Entry: Granular materials enter the cooler from the feeder and chute, guided onto the inclined lifting plate inside the drum.

Tumbling and Cooling: As the drum rotates, lifting flights inside lift the material, allowing it to fall and form a cascading curtain. High-temperature air or cool water flows through the drum, preheating the material and evaporating moisture.

Heat Transfer: The material moves towards the discharge end, where it interacts with the cooler air or water. Heat is transferred from the material to the cooling medium, lowering the material's temperature.

Cleaning and Discharge: A cleaning device removes any material adhering to the drum's inner surface, ensuring efficient operation. The cooled material exits the drum at the lower end, ready for further processing or storage.

*The output will vary according to different materials, feed particle size and other factors