Terbaikmachinery offers efficient dry manganese ore magnetic separators for precise separation in ore processing operations. Our magnetic separation equipment utilizes advanced technology to effectively remove magnetic materials from manganese ore, enhancing beneficiation processes. Trust Terbaikmachinery for expertly crafted magnetic separation solutions that ensure optimal performance and maximize mineral recovery.

1. Beneficiation of Weakly Magnetic Minerals

The dry manganese ore magnetic separator is used for the beneficiation of weakly magnetic minerals such as:Hematite,Limonite

Ilmenite,Wolframite,Tantalite

2. Iron Removal and Purification of Non-Metallic Minerals

It is also employed in the iron removal and purification processes for non-metallic minerals, including:Quartz,Feldspar,Nepheline,Fluorite,Sillimanite,Spodumene

Kaolin

Challenges in Manganese Ore Beneficiation

Most manganese ores are fine-grained and contain high phosphate and high iron content, along with associated beneficial metals, which complicates the beneficiation process. Commonly used manganese ore beneficiation methods include:

Mechanical Separation: Washing, screening, gravity separation, strong magnetic separation, and flotation.

Pyroconcentration: Thermal methods to concentrate the ore.

Chemical Beneficiation: Chemical processes to extract manganese.

Commonly Used Equipment in Manganese Ore Beneficiation:

Vibrating feeder,Jaw crusher,Vibrating screen,Feeder,Ball mill,Spiral classifier,Mixing barrel,Flotation machine

Manganese Minerals

Manganese is found in various minerals, but only a few have real value for mining as manganese ore. Key manganese minerals include:

Pyrolusite (primary ore)

Hard manganese ore

Marsh manganese ore

Others like limonite and black manganese (mixed minerals)

Rhodochrosite (usually found in siderite)

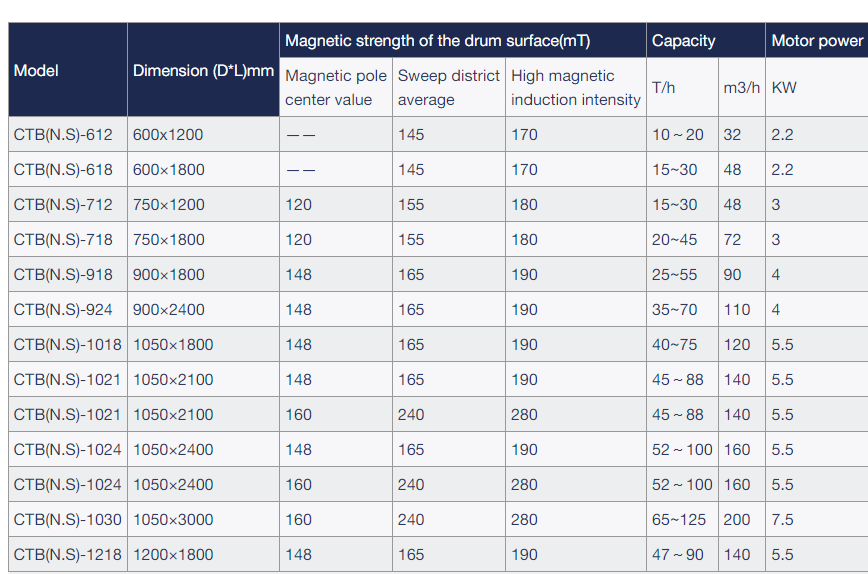

Permanent-Magnetic Drum Magnetic Separator

CTB Series Permanent-Magnetic Drum Separator: Used in mines and coal preparation plants to separate wet fine magnetic substances or to remove magnetic substances from non-magnetic materials.

Permanent Magnetic Drum Separator: Utilized in mines and coal separating factories for the same purpose as the CTB series.

Types of Tanks in Magnetic Separators

The magnetic separators have three types of tanks in the same

cylinder, each suited for different granularity and separation processes:

Half Counter Current Slot (CTB)

Counter Current Slot (CTN)

Downstream Slot (CTS)

These variations cater to different separation requirements and ensure effective processing of various types of materials.

Economies of Scale: The use of dry manganese ore magnetic separators can create economies of scale, making large-scale manganese ore processing more cost-effective.

Remarkable Beneficiation Effect: The separator provides a significant improvement in the beneficiation process, effectively separating magnetic minerals from non-magnetic ones.

High Enrichment of Hard Manganese Ore: The equipment offers high beneficiation enrichment for hard manganese ore, with excellent classification indexes, ensuring high-quality separation.

Low Power Consumption: The magnetic separator operates with low power consumption, making it an energy-efficient choice for manganese ore beneficiation.

Simple Structure and Maintenance: The design of the separator is straightforward, which simplifies maintenance and reduces operational complexities.

The dry manganese ore magnetic separator is highly efficient, offering substantial benefits including cost savings, effective beneficiation, high enrichment of hard manganese ore, low energy usage, and ease of maintenance. These advantages make it a valuable tool in manganese ore processing.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

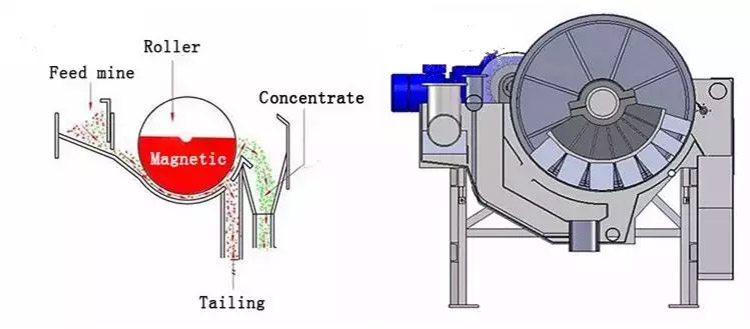

The dry manganese ore magnetic separator operates based on the principle of magnetic attraction and separation. Here’s how it works:

Slurry Entry: The slurry, containing a mix of magnetic and non-magnetic minerals, enters the magnetic field area through the feeding hopper.

Magnetic Attraction: Within the magnetic field, strong magnetic minerals are attracted to and adhere to the surface of the rotating cylinder.

Non-Magnetic Mineral Removal: Weak magnetic and non-magnetic minerals are washed away by the water flow, moving out of the magnetic field area.

Magnetic Mineral Rotation: The magnetic minerals that are adsorbed onto the cylinder's surface rotate with the cylinder as it turns.

Concentration and Separation: As the cylinder moves out of the magnetic field area, the magnetic minerals are separated from the non-magnetic ones. The washing water flushes the magnetic minerals into the concentrate tank.

Completion of Separation: The non-magnetic minerals, which have been washed out, are discarded, while the magnetic minerals collected in the concentrate tank are ready for further processing.

The dry manganese ore magnetic separator uses a magnetic field to attract and separate magnetic minerals from non-magnetic ones. The slurry is fed into the magnetic field, where strong magnetic minerals adhere to a rotating cylinder. Non-magnetic minerals are washed away, and the magnetic minerals are collected and flushed into a concentrate tank, completing the separation process.

*The output will vary according to different materials, feed particle size and other factors