Terbaikmachinery offers Spring Cone Crushers for efficient crushing solutions in various industries. Our Spring Cone Crushers ensure reliable performance, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted crushing solutions that deliver superior results and optimize your material processing operations.

PYB900 Spring Cone Crusher Manufacturer with All Models

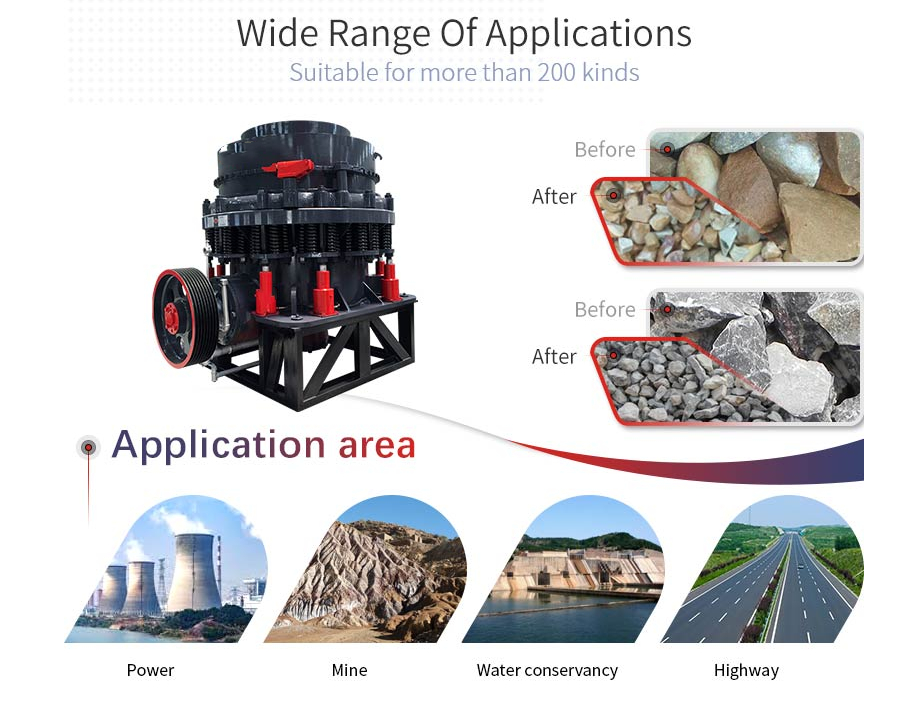

The PY Cone Crusher is widely used for secondary and fine crushing in the fields of mining, chemical industry, building materials, metallurgy and so on. It can crush materials with Moh’s scale in middle and high hardness, such as ironstone, copper ore, limestone, quartz, granite, rock and so on. The standard type (PYB) is applied to secondary crushing; the medium type (PYZ) and the short-head (PYD) are applied to fine crushing.

PYB spring cone crusher combines the former Soviet Union technology with the cone crusher of the 1980s international advanced technology. It is developed on the original basis.Its unique spring insurance system as an overload protection device can effectively deal with the situation of metal foreign matter passing through the crushing chamber and protect the machine from damage; the product material size is relatively uniform, in a cubic shape, and the wear of the working surface of the moving cone is also relatively uniform.

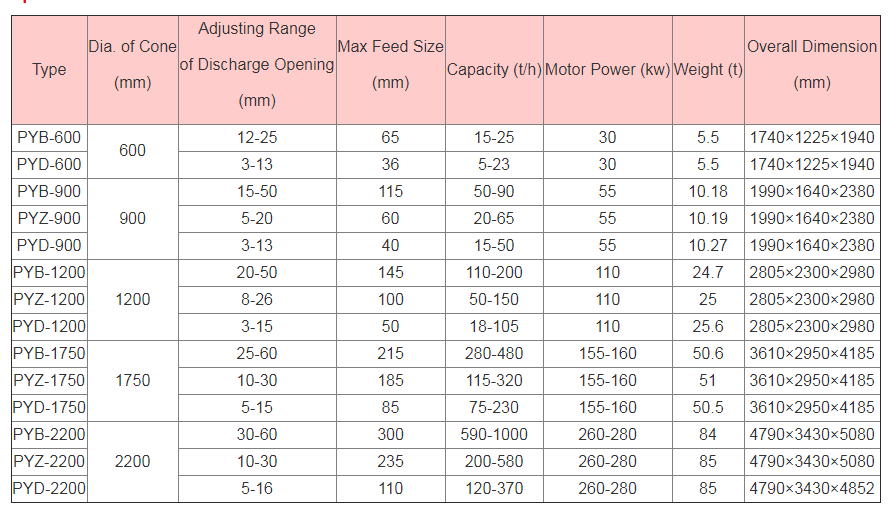

Compared with PYB-600, PYB-900 has greater crushing capacity and is suitable for handling medium-sized material crushing tasks; PYB-1200 is suitable for large mines and sand and gravel production lines and other occasions, with high production capacity and crushing efficiency. PYB-1750 and PYB-2200 are large equipment among cone crushers, suitable for occasions with extremely high requirements for crushing capacity.

High-efficiency crushing principle: Spring cone crusher adopts the principle of lamination crushing, which greatly reduces the needle-like material and improves the processing capacity. The combination of its high-performance crushing chamber and high crushing frequency significantly improves the processing capacity.

Over-iron protection mechanism: The equipment design adopts a two-way over-iron release hydraulic cylinder. When unbreakable objects such as iron blocks enter the crushing chamber, it can be automatically released, reducing downtime and improving equipment reliability.

Uniform particle size: The product crushed by the spring cone crusher is uniform in particle size and in a cubic shape, and the wear of the working surface of the moving cone is also relatively uniform.

![_]T75]B8_2EN@W1@(`]`~6V.png](/static/upload/image/20241126/_]T75]B8_2EN@W1@(`]`~6V.png)

FAQ: How to choose a suitable spring cone crusher ?

1. what is the raw material you want to crush ?

2. what is the input size of your raw stone ?

3. what is the capacity per hour do you need ?

4. what is the output size do you need ?

Answer:

these are normal qustions about spring crusher

For example:

PYB 600 Spring cone crusher

input size: < 65 mm output size:12 - 25 mm

capacity:15 - 25 ton per hour power: 30 kw

PYB 900 Spring cone crusher

input size: < 115 mm output size:15 - 50 mm

capacity:50 - 90 ton per hour power: 55 kw

PYB 1200 Spring cone crusher

input size: < 145 mm output size:20 - 50 mm

capacity:110 - 200 ton per hour power: 110 kw

you can check the parameter below.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Working principle What Is The Working Principle Of The Spring Cone Crusher?

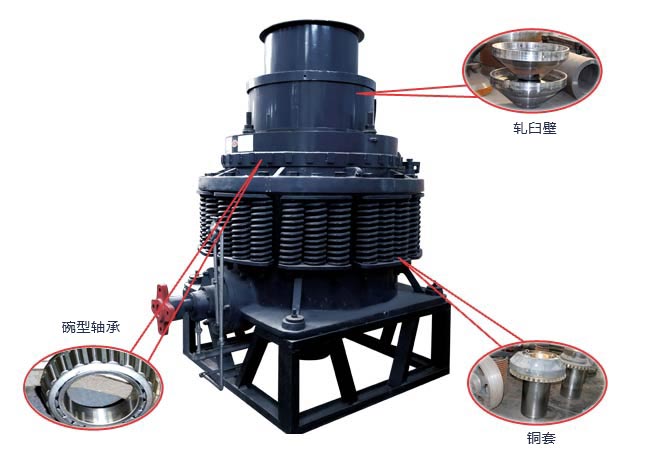

When the PY Cone Crusher is working, the motor drives the eccentric bearing bushing via spring coupling, transmission shaft and a couple of cone gear wheel. The crushing cone axis is forced to swing by the eccentric bearing bushing, which makes the mantle close to the bowl liner and far away from the bowl liner from time to time. The raw materials are pressed, impacted and finally crushed in the crushing cavity.

Related:

What is the spare parts of Spring cone crusher ?

1. Mantle is Mn13Cr2 ,it can use 6-10 months ,we suggest you buy two sets as standby .

2. concave is Mn13Cr2 ,it can use 6-10 months ,we suggest you buy two sets as standby.

3.Bowl liner is copper ,it can use 12 months ,we suggest you buy one set as standby.

}U0Z6B.png)

About wearing parts

The accessories and wearing parts of the Spring cone crusher are crucial to the normal operation and crushing efficiency of the equipment. In daily use, special attention should be paid to the protection and maintenance of these parts and worn or damaged parts should be checked and replaced in time to ensure the long-term stable operation of the crusher.

The wearing parts of the spring cone crusher include a mantle, concave, Bowl liner, eccectirc shaft, eccentric sleeve . The concave and mantle are the main working part and bears a large impact and extrusion force, so the wear rate is relatively high. Powerful, wearing parts need to be replaced regularly, choose wear-resistant materials to increase the life of the equipment. Terbaik machinery is made of high manganese steel, which has good casting performance, wear resistance, and increases the stability of the equipment.

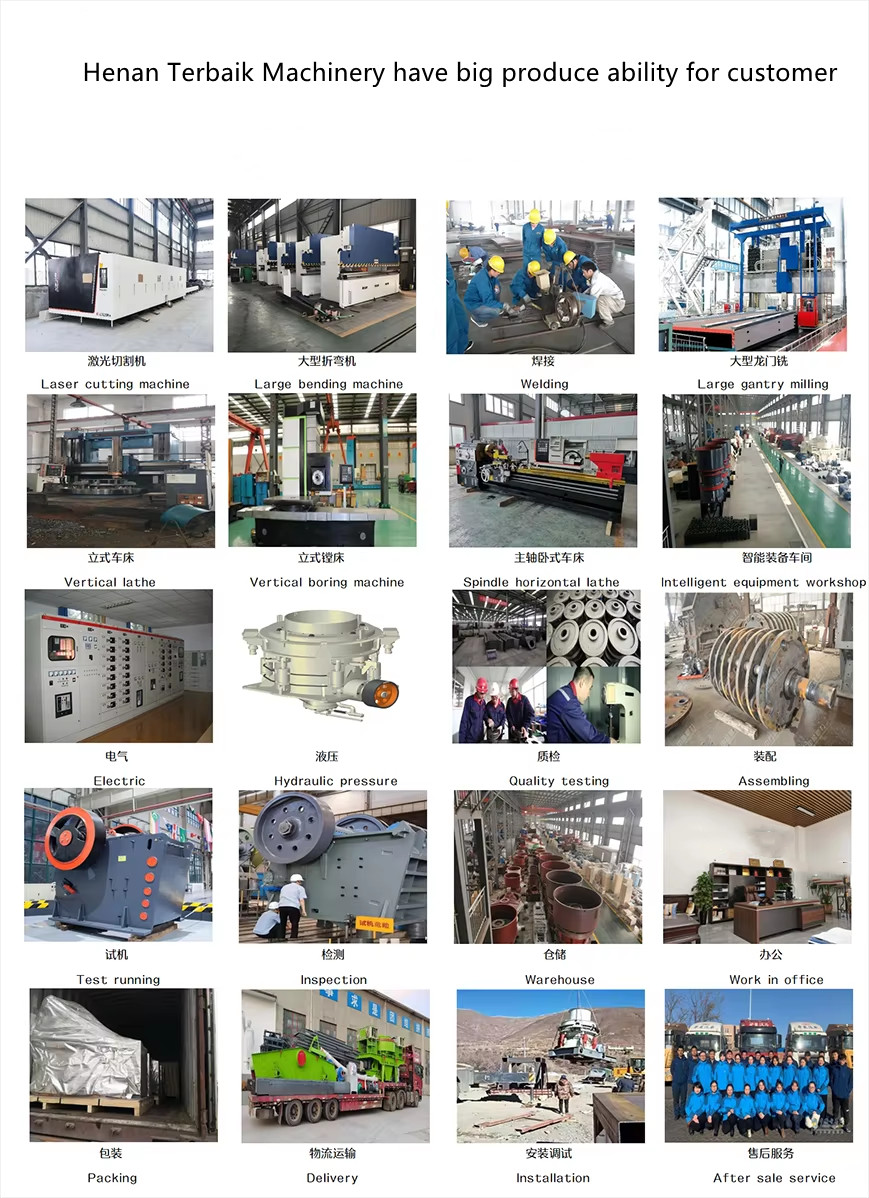

About delivery standards

Terbaik machinery has extremely complete delivery standards, a series of standards and regulations formulated to ensure that the ordered goods can be delivered completely and accurately according to the needs and requirements of customers. These standards usually involve quantity, specifications, quality, packaging, documents and time, etc., to ensure the smooth progress of the delivery process and improve customer satisfaction.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors