Efficient brewer's spent grain dryer for breweries and feed manufacturers. Converts wet BSG into high-protein animal feed with automated drying technology. Learn more about its benefits and features.

Brewer's spent grain (BSG) is the solid residue left after the brewing process, consisting of malt, rice, and hops that have undergone mashing and filtration. With high moisture content (around 85%) and a sticky texture, BSG presents challenges in further processing. However, it can be converted into high-value animal feed, contributing to economic gains while reducing environmental pollution.

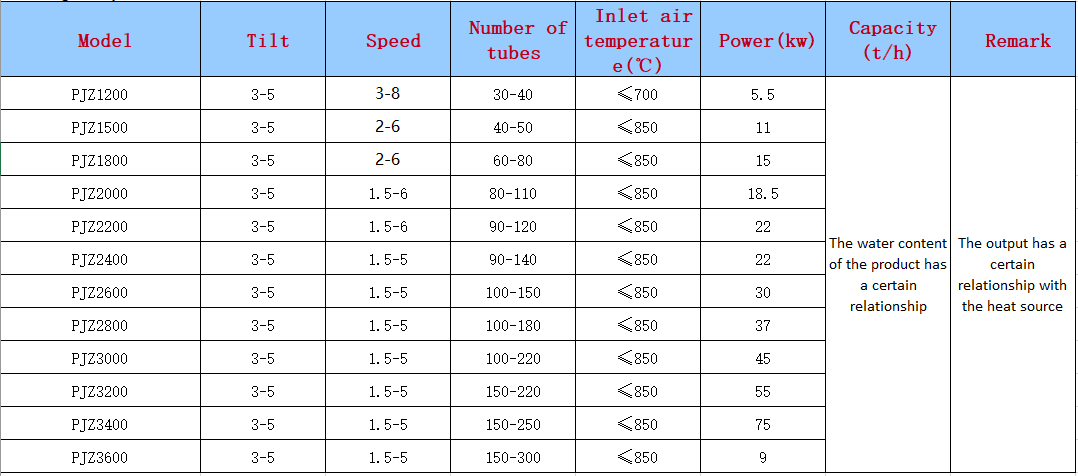

The brewer's spent grain dryer machine efficiently addresses the high moisture and stickiness of BSG, reducing its water content to approximately 10%. This makes it suitable for feed production. Widely adopted by breweries and feed manufacturers, the machine dehydrates and dries BSG, ensuring consistent quality and performance.

The dryer system comprises a heat source, feeding system, rotary drum, discharge system, induced draft fan, unloading device, and control panel. Wet BSG enters the rotary drum, where lifters evenly distribute the material for optimal heat and mass transfer. This ensures rapid and uniform drying.

1. High Automation and Capacity:

Fully mechanized operations allow large-scale production and continuous operation.

2. Robust and Efficient Design:

Simple structure ensures smooth material flow with minimal resistance, enabling easy operation and stable performance.

3. Low Maintenance Costs:

Reduced operational failures, low energy consumption, and minimal maintenance requirements ensure cost efficiency.

4. Uniform Drying:

The dryer delivers consistent drying results, making the final product suitable for high-protein animal feed production.

.jpg)

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Wet BSG is fed into the rotary drum of the dryer, equipped with spiral lifters that continuously lift and spread the material. Built-in striking devices prevent material buildup on the drum walls and lifters. The dispersed material interacts with hot air supplied by the induced draft fan, accelerating heat and mass transfer.

The process ensures thorough water evaporation, reducing moisture content from 85% to approximately 10%. The dried product is discharged from the outlet, ready for use in high-protein feed production. This automated drying system transforms BSG processing into an efficient, industrial-scale operation with minimal labor requirements.

*The output will vary according to different materials, feed particle size and other factors