.jpg)

Efficient chicken manure dryer machine for poultry farms. Produces high-quality organic fertilizer, reduces waste, and promotes sustainable agriculture. Learn more about its advanced features and benefits.

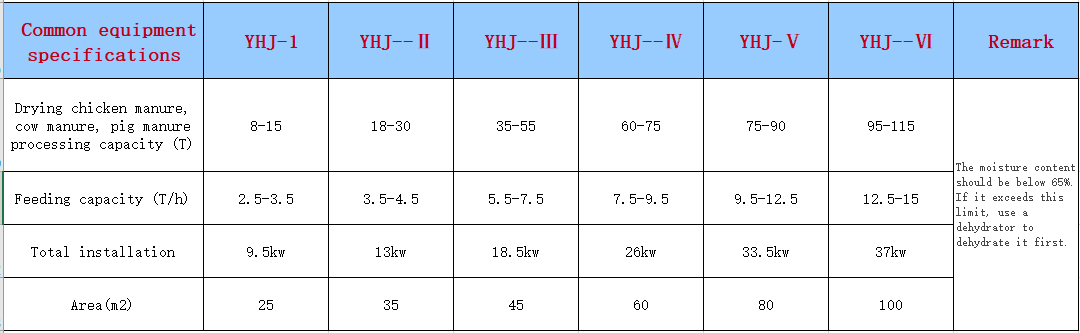

The chicken manure dryer machine is designed for small, medium, and large-scale poultry farms and regions with developed livestock industries. This equipment accommodates various heat sources based on drying requirements, including gas generators, direct and indirect hot air furnaces, thermal oil, electric heating, and steam. It is suitable for drying materials with a moisture content of less than 65%, such as chicken manure, duck manure, livestock waste, slaughterhouse by-products, and other organic waste. The machine is an effective solution for transforming waste into valuable resources, reducing breeding costs, and mitigating environmental pollution.

.jpg)

Advanced Production Process:

The machine processes fresh chicken manure with a moisture content of 65% through high-temperature drying, sterilization, and decomposition, producing organic fertilizer with a moisture content of less than 13%.

High-Quality Output:

The resulting organic fertilizer contains essential nutrients for crops, such as 2.6% nitrogen, 3.5% phosphorus, 2.5% potassium, 16-25% crude protein, and 45% organic matter. It is ideal for green, non-toxic crop cultivation and can also serve as feed for fish, cattle, and pigs.

High Efficiency:

The rotary drum drying system is highly automated, capable of continuous operation, and offers large-scale production capabilities.

Robust Construction:

The machine features a simple, durable design that ensures smooth material flow, easy operation, and minimal resistance during drying.

Low Maintenance Costs:

With fewer failures, reduced maintenance expenses, and lower energy consumption, this dryer is cost-effective.

Versatile Applications:

The dryer works efficiently across a wide range of materials, ensuring consistent drying quality.

Environmental Benefits:

Besides drying, the machine achieves sterilization and deodorization, enhancing environmental safety.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The chicken manure dryer consists of a heat source, feeding system, rotary drum, material crusher, discharging system, fan, unloading device, and control panel. After pre-dehydration, wet materials enter the drum dryer. The rotary drum is equipped with lifting plates to ensure the material is evenly dispersed and exposed to hot air for maximum heat and mass transfer.

As materials move through the drum, they are preheated and dehydrated. The built-in cleaning mechanism prevents material buildup on the drum walls, maintaining efficient drying performance. Finally, the dried materials exit the system as low-moisture, nutrient-rich organic fertilizer.

.jpg)

*The output will vary according to different materials, feed particle size and other factors