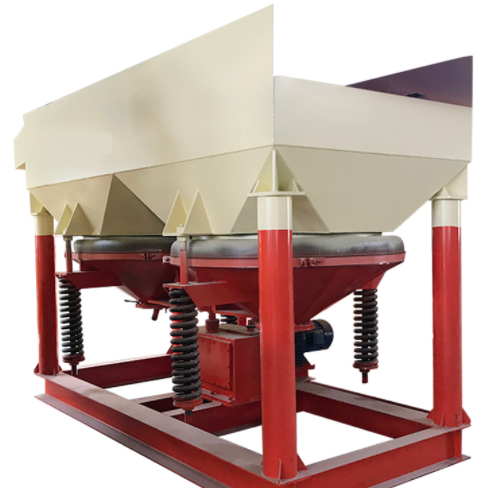

Explore Terbaikmachinery's high-performance jig machines designed for efficient mineral separation processes. Our gravity concentration equipment utilizes advanced jigging technology to effectively separate valuable minerals from waste material, enhancing ore beneficiation and mineral processing operations. Trust Terbaikmachinery for expertly crafted jigging solutions that ensure optimal performance and maximize mineral recovery.

Introduction:

A jig machine is a type of equipment that separates light and heavy minerals based on their different sedimentation speeds in a vertical alternating water flow. This separation technique is widely used in mineral dressing or beneficiation systems.

Applications:

Mineral Ores:Hematite, Limonite, Sand Gold Ore, Manganese Ore, Tungsten Ore, Tin Ore, Tantalum-Niobium (Ta-Nb) Minerals, Mercury Ore, Fluorite Ore, Barite Ore

Smelting Slag Recovery:, Silica-Manganese Slag, Ferro-Manganese Slag, Nickel Slag, Steel Iron Slag, Sulfate Slag

Other Applications:

Recovery of metals or alloy particles from various types of smelting slag.

Beneficiation and extraction of valuable minerals from the azure quarries and other similar deposits.

By utilizing the principle of different sedimentation speeds, jig machines effectively separate minerals, making them versatile and essential in various mineral processing and metal recovery operations.

Adjustable Stroke and Frequency:

Stroke and jig frequency are easy to adjust, allowing for fine-tuning of the separation process.

Advanced frequency conversion speed control technology enhances operational convenience and management.

Compact Design:

Requires a small cover area while providing a high processing capacity per unit area.

Energy Efficiency and Environmental Friendliness:

Energy-saving design with high enrichment efficiency.

Environmentally friendly operation with low energy consumption.

High Recovery Rate and Capacity:

Achieves a high recovery rate of valuable minerals.

Capable of handling a large volume of material.

Versatility:

Adjustable stroke and frequency for each slot accommodate a wide range of particle sizes.

Effective for a broad range of ore types.

Operational Stability and Maintenance:

High stability during operation.

Simple to operate and maintain, reducing the need for complex procedures.

These advantages make the jig machine a versatile and efficient choice for mineral processing and ore beneficiation.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

A jig machine is a type of mineral processing equipment that employs a side-moving rectangular jig with two rows and four chambers to separate minerals based on their densities.

1.Motor and Reduction Gears:

The motor drives reduction gears through a transmission system.

These gears have eccentric adjusting devices at both output ends.

2.Eccentric Adjusting Devices:

These devices drive a connecting rod.

The connecting rod, in turn, drives the driving pan to perform an alternating motion.

3.Wave Generation:

The alternating motion of the driving pan extrudes the liquid in the cell body, creating waves.

These waves move through a screen and impact the ore placed on the screen.

4.Ore Separation:

The impact of the waves causes the ore to enter a state of free-fall within the liquid.

Due to different densities, ore grains have varying falling speeds in the liquid.

This difference in falling speed results in the natural separation of the ore.

5.Discharge Process:

Heavier ore particles settle and are discharged out of the cell body after proper adjustment.

Lighter ore particles float and are discharged through the waste-discharging mouth.

6.Efficiency and Improvements:

The jig machine uses a cone slide valve, which reduces the failure rate by 80%.

It has low energy consumption and can separate different materials efficiently.

The processing capacity is improved by more than 35%.

In summary, the jig machine separates minerals based on density differences, using a combination of mechanical motion and water waves to achieve effective mineral beneficiation.

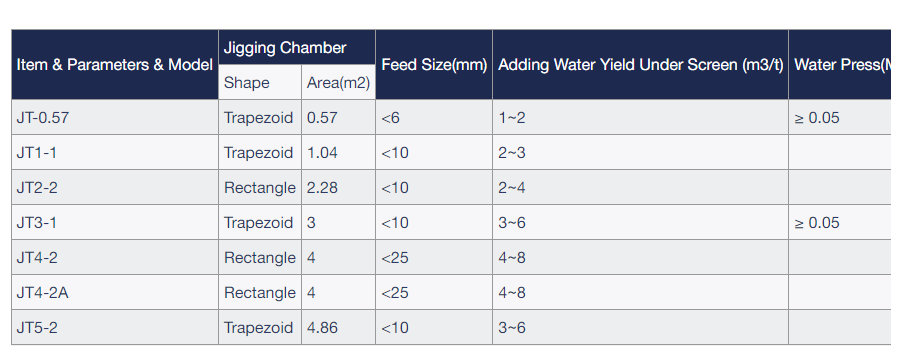

*The output will vary according to different materials, feed particle size and other factors