.jpg)

Henan Terbaik's River Sand Dryer is a durable, high-efficiency machine designed for river sand drying applications. It offers superior energy savings, high thermal efficiency, and easy installation. With its compact, durable structure, this dryer is ideal for construction, cement plants, and dry mortar production lines, providing a low-moisture, high-quality sand solution for various industrial needs.

The River Sand Dryer is specialized equipment designed for drying river sand, widely applicable in various industries. Processed river sand can be used as a key ingredient in external wall insulation mortar, and in concrete, it serves as a granular, loose material for structural or filler applications. River sand, with its smooth and clean particles, is naturally sourced, making it an ideal choice in construction for enhancing the longevity of buildings. Henan Terbaik Machinery Co., Ltd. has developed a river sand dryer that effectively meets drying requirements, optimized for durability and energy efficiency. The dryer includes a drum, roller rings, gears, support rollers, lifting plates, hot air ducts, and a hot air furnace, all working together to streamline sand flow within a tilted drum for efficient drying.

.jpg)

High Cost-Efficiency: The investment in our river sand dryer is approximately 20% of similar imported products.

High Durability: Constructed with wear-resistant manganese plates, offering 3-4 times the durability of standard steel plates.

Enhanced Heat Efficiency: Provides over 40% improvement in thermal efficiency compared to traditional single-drum dryers.

Fuel Flexibility: Compatible with various fuels, including anthracite, bituminous coal, coal gangue, oil, and gas, and can handle materials under 20-40mm in size.

Space-Saving Design: Reduces the footprint by around 60%, lowering construction costs by the same amount and ensuring easy installation.

Leak-Free Sealing: Resolves the challenges of airtight sealing.

Low Output Temperature: The discharge temperature is ≤60°C, making it suitable for direct storage without additional cooling.

Optimized Dust Control: The outer drum temperature remains ≤60°C, with exhaust gases <120°C, extending the bag filter lifespan by more than double.

Energy Savings: Reduces coal consumption to one-third of traditional single-drum dryers and saves 40% in electricity.

Moisture Control: Reduces initial moisture from 15% to a final moisture content of 0.5-1%, making it ideal for cement plants, slag powder, and dry mortar production lines.

.jpg)

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The river sand drying process integrates additional equipment, including a lifting device, disc feeder, belt conveyor, cyclone dust collector, and induced draft fan. River sand enters through a hopper and feeder pipe, with gravity guiding it into the dryer. Heat enters from the lower end, counterflowing with the sand to maximize thermal exchange within the drum. With the drum rotation, gravity helps sand move towards the discharge end, where it is transported by conveyor belts to a vibrating screen for final product sorting. This ensures a high-quality dried sand output.

.jpg)

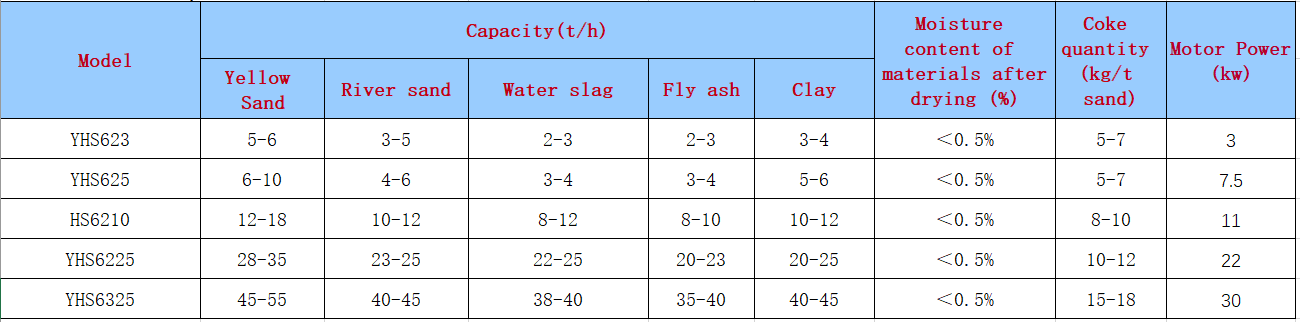

*The output will vary according to different materials, feed particle size and other factors