.jpg)

Single cylinder hydraulic cone crusher is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc. It can break or crush all kinds of medium hard or harder ore for mining, chemical building, materials and other industrial sectors.

Single-cylinder hydraulic cone crusher is a cone crushing equipment that uses a single-cylinder hydraulic system and is mainly used for medium and fine crushing operations.

It is suitable for crushing high-hardness and highly abrasive ores and rocks, especially widely used in the crushing of metal ores and building sand and gravel.

DP100 and DP430 single-cylinder cone crushers have the characteristics of high crushing efficiency, moderate processing capacity, and wide application range.

DG440 and DP660 single-cylinder cone crusher has a larger production capacity (200-650t/h), higher crushing efficiency, and a wider range of applications.

The single-cylinder hydraulic cone crusher adopts advanced design concepts, making it compact in structure, small in space, and easy to install and layout.

The single-cylinder hydraulic cone crusher adopts a steep slope cone design with a large swing frequency and large inclination, making its processing capacity about 40% greater than that of ordinary cone crushers.

Why Choose the DP single-cylinder hydraulic cone crusher?

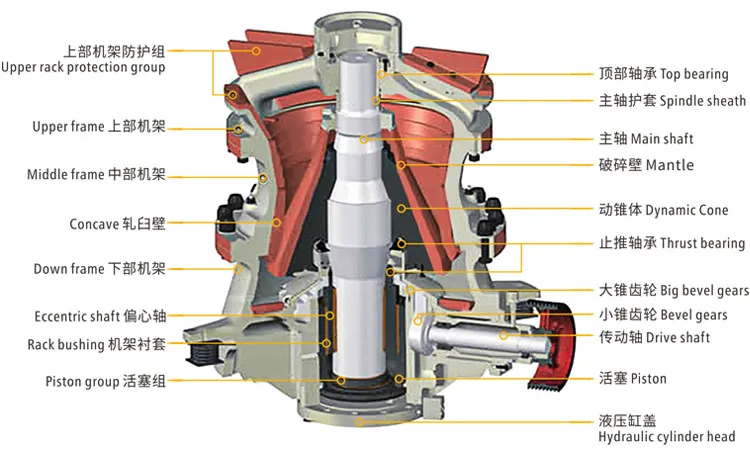

Robust Support for Main Shaft:

The DP cone crusher features support at both the upper and lower ends of the main shaft. This design enables it to withstand greater crushing force and stroke, resulting in higher crushing efficiency.

Convenient Discharge Port Adjustment:

The main shaft of the single-cylinder cone crusher is mounted on a bottom hydraulic cylinder. This cylinder can be adjusted up and down to change the size of the discharge port, making the adjustment process straightforward and convenient.

Quick Replacement of Wear Parts:

The joint surface between the rolling mortar wall and the cone is stable and firm, allowing for quick replacement of vulnerable parts without the need for additional filling supplements. This design saves time on the replacement of wearing parts.

Double Safety Control Systems:

The DP cone crusher is equipped with both hydraulic and lubrication systems, ensuring overload protection and optimal bearing lubrication. This dual system enhances the machine's safety and reliability.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

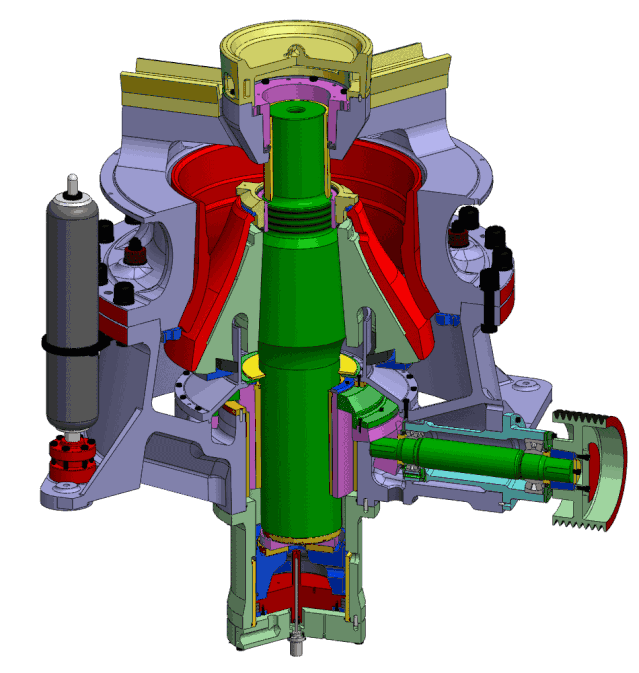

What Is The Working Principle Of The Single-cylinder hydraulic Cone Crusher?

When the single-cylinder hydraulic cone crusher is working, motor drive the eccentric sleeve by v-belts, transmission shaft and transmission gear. Dynamic conerotary pendulum moved with the action of eccentric sleeve, the moving cone and fixed cone sometimes near sometimes deviation. Material is squeezed in the crushing cavity, impact and breakage, broken material discharge from the bottom.

The raw material is high strength cast iron, with good mechanical property, as well as good ability of absorbing the energy of crusher's vibration. It's a great help to make the rotation of main shaft running steady, which can continuously stable the output of your crusher. The heat treatment of tempering is applied to release the internal stress. It's a great help to prevent the part's dimension change in the daily operation of your crusher. It obviously can prolong the life of your crusher. The final machining is carried by CNC machine to ensure each dimension tolerance, which helps to make your assembly easy and fast, to improve the efficiency of your production and maintenance.

Single Cylinder Hydraulic Cone Crusher Specifications:

Model | DP100S | DP100 | DP430S | DP430 | DP440S | DP440 | DP660S | DP660 | DP870 |

Weight (kg) | 7350 | 5700 | 12000 | 9200 | 19300 | 14300 | 35700 | 26800 | 49800 |

Maximum inspection weight (kg) | 2800 | 2000 | 5200 | 3000 | 8200 | 4800 | 16800 | 8600 | 13200 |

Power(kW) | 90 | 90 | 132 | 132 | 220 | 220 | 315 | 315 | 500 |

Model | Cavity | Max feeding size (mm) | The capacity of Corresponding Discharge opening size(t/h) | |||||||||||||||

19mm | 22mm | 25mm | 29mm | 32mm | 35mm | 38mm | 41mm | 44mm | 48mm | 51mm | 54mm | 60mm | 64mm | 70mm | 76mm | |||

DP100S | M Medium | 170 | 85-90 |

| 105-145 | 125-175 |

| 145-200 |

| 165-215 |

|

|

|

|

|

|

|

|

DP430S | EC Supre Coarse | 360 |

|

| 126 | 138-173 | 147-230 | 156-293 | 165-310 | 174-327 | 183-344 | 196-306 | 205-256 |

|

|

|

|

|

C Coarse | 300 |

| 108 | 116-145 | 127-199 | 135-254 | 144-270 | 152-285 | 161-301 | 196-264 | 108 |

|

|

|

|

|

| |

MC Medium Coarse | 235 | 91 | 98-123 | 106-166 | 116-218 | 124-232 | 131-246 | 139-261 | 147-275 | 154-241 | 165 |

|

|

|

|

|

| |

DP440S | EC Super Coarse | 450 |

|

|

|

|

| 267 | 282-353 | 298-446 | 313-563 | 334-601 | 350-524 | 365-456 |

|

|

|

|

C Coarse | 400 |

|

|

| 225 | 239-299 | 254-381 | 269-484 | 284-511 | 298-448 | 318-398 | 333 |

|

|

|

|

| |

MC Medium Coarse | 300 |

|

| 195 | 214-267 | 228-342 | 242-435 | 256-461 | 270-486 | 284-426 | 303-378 | 317 |

|

|

|

|

| |

DP660S | EC Super Coarse | 560 |

|

|

|

|

|

|

| 349 | 368-460 | 392-588 | 410-718 | 428-856 | 465-529 | 489-978 | 525-1050 | 562-983 |

C Coarse | 500 |

|

|

|

|

|

| 318 | 336-420 | 353-618 | 376-753 | 394-788 | 411-823 | 446-892 | 469-822 | 504-631 | ||

Model | Cavity | Max feeding size (mm) | The capacity of Corresponding Discharge opening size | ||||||||||||||

6mm | 8mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 44mm | 51mm | 57mm | 64mm | 71mm | |||

DP100 | M Medium | 105 |

|

| 55-60 | 60-85 | 65-95 | 70-100 | 75-90 |

|

|

|

|

|

|

|

|

MF Medium fine | 85 |

| 45-50 | 50-70 | 55-80 | 60-85 | 65-90 | 65-80 |

|

|

|

|

|

|

|

| |

EF Super fine | 32 | 40-55 | 40-60 | 45-70 | 55-75 | 60-75 | 65 |

|

|

|

|

|

|

|

|

| |

DP430 | EC Super coarse | 185 |

|

|

| 69-108 | 75-150 | 80-161 | 86-171 | 91-182 | 104-208/ | 115-208 |

|

|

|

|

|

C Coarse | 145 |

|

|

| 66-131 | 71-142 | 76-152 | 81-162 | 86-173 | 98-197 | 109-150 |

|

|

|

|

| |

MC Medium coarse | 115 |

|

| 57 | 62-140 | 67-151 | 72-162 | 77-173 | 82-184 | 93-145 |

|

|

|

|

|

| |

M Medium | 90 |

|

| 64-84 | 69-131 | 75-142 | 80-152 | 86-162 | 91-154 | 104 |

|

|

|

|

|

| |

MF Medium fine | 75 |

| 61 | 65-106 | 70-115 | 76-124 | 81-126 | 87-114 | 92 |

|

|

|

|

|

|

| |

F Fine | 50 | 48-78 | 51-83 | 54--88 | 59-96 | 63-103 | 68-105 | 72-95 | 77 |

|

|

|

|

|

|

| |

EF Super Fine | 35 | 70-90 ,80%<5mm-5.6mm | |||||||||||||||

DP440 | EC Super coarse | 215 |

|

|

|

| 114-200 | 122-276 | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 |

|

|

|

|

C Coarse | 175 |

|

|

| 101 | 109-218 | 117-292 | 125-312 | 133-332 | 151-378 | 167-335 | 183-229 |

|

|

|

| |

MC Medium coarse | 140 |

|

|

| 97-122 | 105-262 | 113-282 | 120-301 | 128-320 | 146-328 | 161-242 |

|

|

|

|

| |

M Medium | 110 |

|

|

| 117-187 | 126-278 | 136-298 | 145-318 | 154-339 | 175-281 | 194 |

|

|

|

|

| |

MF Medium fine | 85 |

|

| 114 | 124-227 | 134-245 | 144-263 | 153-281 | 163-299 | 186-248 |

|

|

|

|

|

| |

F Fine | 70 |

| 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | 129-236 | 137-251 | 156-208 |

|

|

|

|

|

| |

EF Super fine | 38 | 100-125, 80%<6mm-7.5mm | |||||||||||||||

DP660 | EC Super coarse | 270 |

|

|

|

| 177 | 190-338 | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 328-511 |

|

|

|

CX Super coarse | 235 |

|

|

|

| 174-194 | 187-374 | 200-488 | 212-519 | 242-592 | 268-654 | 293-521 | 323-359 |

|

|

| |

C Coarse | 215 |

|

|

|

| 171-190 | 184-367 | 196-480 | 209-510 | 238-582 | 263-643 | 288-512 | 317-353 |

|

|

| |

MC Medium coarse | 175 |

|

|

|

| 162-253 | 174-426 | 186-455 | 198-484 | 226-552 | 249-499 | 273-364 |

|

|

|

| |

M Medium | 135 |

|

|

|

| 197-295 | 211-440 | 226-470 | 240-500 | 274-502 | 302-403 |

|

|

|

|

| |

MF Medium fine | 115 |

|

|

| 192 | 207-369 | 222-396 | 237-423 | 252-450 | 287-451 | 318-363 |

|

|

|

|

| |

F Fine | 90 |

|

|

| 195-304 | 210-328 | 225-352 | 241-376 | 256-400 | 292-401 | 323 |

|

|

|

|

| |

EF Super fine | 65 |

|

|

| 211-293 | 227-316 | 244-298 | 261-290 |

|

|

|

|

|

|

|

| |

DP870 | EC Super coarse | 300 |

|

|

|

|

|

| 448-588 | 477-849 | 544-968 | 601-1070 | 658-1172 | 725-1291 | 782-1393 | 849-1512 | 906-1331 |

C Coarse | 240 |

|

|

|

|

| 406 | 433-636 | 461-893 | 525-1018 | 581-1125 | 636-1232 | 700-1357 | 756-1464 | 820-1461 | 876-1286 | |

MC Medium coarse | 195 |

|

|

|

|

| 380-440 | 406-723 | 432-837 | 492-954 | 544-1055 | 596-1155 | 657-1272 | 708-1373 | 769-1370 | 821-1206 | |

M Medium | 155 |

|

|

|

|

| 400-563 | 428-786 | 455-836 | 519-953 | 573-1054 | 628-1154 | 692-1271 | 746-1372 | 810-1248 | 865-1098 | |

MF Medium fine | 100 |

|

|

|

| 379-424 | 407-716 | 434-765 | 462-814 | 527-928 | 852-942 | 638-789 | 702 |

|

|

| |

F Fine | 90 |

|

|

| 357-395 | 385-656 | 414-704 | 442-752 | 470-800 | 535-912 | 592-857 | 649-718 |

|

|

|

| |

EF Medium fine | 80 |

|

| 280-405 | 304-517 | 328-558 | 352-598 | 376-639 | 400-680 | 455-775 | 503-758 | 551-669 |

|

|

| ||

1. As the most traditional cone crusher the spring cone crusher is the earliest model used in the market, with relatively low production capacity and high production cost.

2. Hydraulic cone crusher is further divided into three types: full hydraulic, single-bar hydraulic, and multi-cylinder hydraulic.

3. Single-bar hydraulic cone crusher integrates mechanical, hydraulic, and intelligent control in one crushing structure, with a relatively long service life, convenient replacement and maintenance, low failure rate, and high output.

4. Multi-cylinder hydraulic cone crusher increases the number of cylinders on the basis of a single-bar, which is more convenient to adjust and repair, with a relatively longer service life, better discharge quality, and lower cost.

5. A fully hydraulic cone crusher combines the advantages of a single-bar cone crusher and compound cone crusher, adopts specific crushing frequency and eccentricity, has a high content of medium fineness, high production efficiency, and low energy consumption.

6. Compound cone crusher is a type of cone crusher that combines multiple technical advantages.

7. Mobile cone crushers can be divided into spring cone crushers, single-cylinder cone crushers, multi-cylinder hydraulic cone crushers, full hydraulic cone crushers and other types according to the type of cone crusher carried. There are two types of mobile cone crushers: crawler type and head-pulled type, which are easy to move and transfer.

About delivery standards

Terbaik machinery has extremely complete delivery standards, a series of standards and regulations formulated to ensure that the ordered goods can be delivered completely and accurately according to the needs and requirements of customers. These standards usually involve quantity, specifications, quality, packaging, documents and time, etc., to ensure the smooth progress of the delivery process and improve customer satisfaction.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors