Terbaikmachinery offers shaking tables designed for precise mineral separation in various applications. Our shaking table equipment utilizes gravity concentration to efficiently separate minerals, enhancing ore beneficiation and material separation processes. Trust Terbaikmachinery for expertly crafted shaking tables that deliver superior results and optimize mineral recovery.

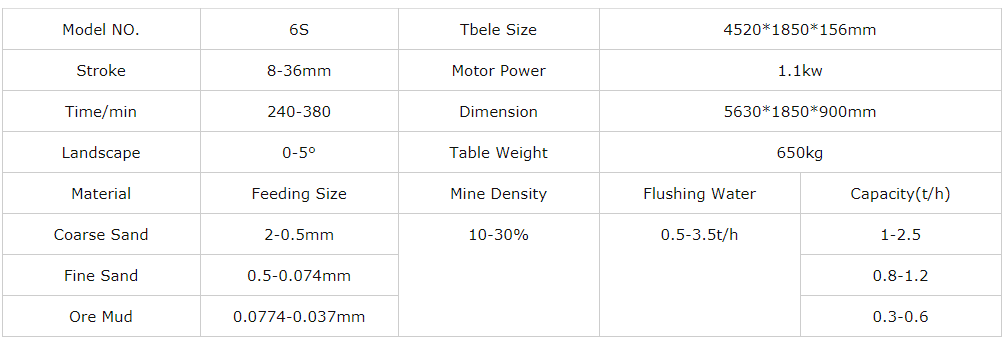

The shaking table, a gravity dressing machine, is essential for separating fine particles of various metals, including gold, silver, zinc, tungsten, iron, manganese, lead, coal, and heavy metal materials. Suitable for different grades of materials such as 2-0.5mm, coarse sand of 0.5-0.074mm, fine sand, and slime of 0.074mm, the shaking table excels in processing tungsten or tin metal ores within the effective recovery range of 2-0.22mm.

Significance in Beneficiation

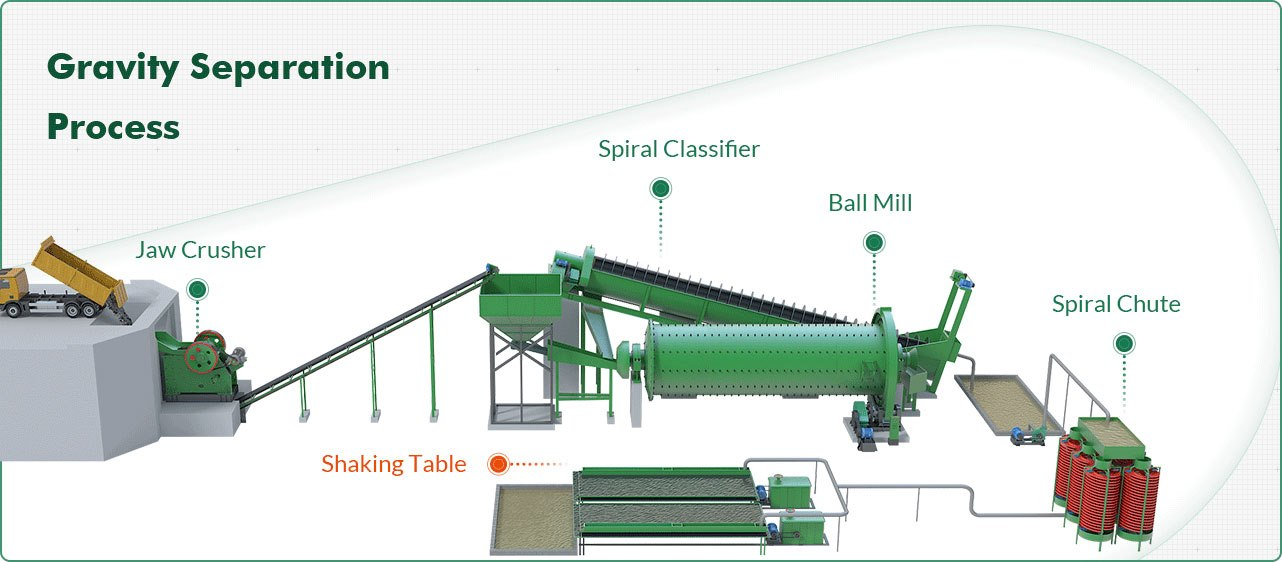

The physical beneficiation process is the most crucial step in sorting ferrous, non-ferrous, precious (Gold, Silver, etc.), and rare metals from primary and secondary sources. The shaking table, an old and reliable technique, is widely used in the mining and recycling industries due to its effectiveness in gravity separation, leveraging the density differences between mineral particles.

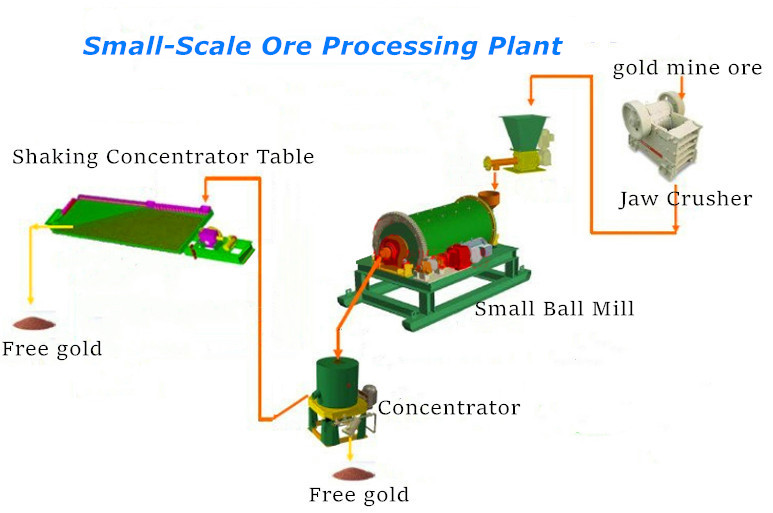

Product Introduction: Gemini Table

The Gemini Table, also known as a precious metal table, operates based on the specific gravity principle, ideal for grain sizes between 30 microns and 2mm. Specially designed for precious metals such as gold, palladium, tantalum, and copper, it maximizes the concentration rate in ore with low energy consumption. Featuring frequently installed mini valves, it allows fine adjustments in the water collector as needed. Available in laboratory and industrial types, the Gemini Table offers versatile solutions for different operational scales.

Product Specifications and Performance

As an OEM & ODM in gold recovery equipment with rich experience and numerous Independent Intellectual Property Rights, Henan Terbaik Mine Machinery provides various models of mini gold dredges with different dimensions and capacities.

Terbaik produces high-performance shaker tables for gravity separation, tailored to different material densities. These tables combine the best of many proven designs, refined after extensive R&D, with the most notable feature originating from a 1909 Deister patent: a ramp and plateau system built into the table top. This design ensures excellent separation between high-density materials, lower density materials, and waste products.

The table design minimizes turbulence in the slurry as it flows across, leading to higher recovery rates of even the finest gold. Terbaik's shaker tables boast a proven ability to capture 95% of gold down to 325 mesh (50 microns) or less, outperforming other gravity recovery systems.

Proven Applications

Hard Rock Mining: Effective for extracting gold and other metals from hard rock sources.

PCB and E-Waste Processing: Efficient in recovering valuable metals from electronic waste.

Scrap Metals and Copper Wire Chops: Ideal for separating metals in recycling processes.

Auto Shred with Contaminated Metals: Useful in automotive recycling for separating metals.

Bottom Ash Containing Precious and Base Metals: Enhances the recovery of valuable metals from incineration ash.

For questions and expert opinions on the appropriate size and accessories needed for specific jobs, the Terbaik team is ready to provide support and answer any inquiries.

The shaking table remains an indispensable tool in modern mining and recycling, offering efficient, reliable separation of fine particles and valuable metals from various sources.

Machined Grooves: Thick rubber table tops with machined grooves reduce agitation in the slurry, enhancing the recovery of finer material.

Durable Table Top Material: Made from EPDM, the same material as torch-down roofing, ensuring long life even when exposed to the elements.

Smooth Shaking Motion: A cyclical shaking motion without bumps or jerks results in less slurry agitation and higher fine gold recovery.

Stability: No anchoring required when additional weight is added to the frame base.

Simple Mechanical Design: Ensures trouble-free service and maintenance.

Adjustable Settings: Easy to adjust and tune for optimal performance.

Importance of Shaking Tables in the E-Waste Recycling Industry

Shaking tables play a critical role in the e-waste recycling industry, particularly in the separation of precious and rare metals from complex electronic waste structures. Here’s why they are essential:

Separation by Density: Shaking tables can effectively separate precious and rare metals from glass fiber and other plastic structures based on density differences.

Three-Part Division: The process divides materials into three categories: concentrate, intermediate, and residue. Metals in the concentrates and intermediates are easier to obtain with high purity, while the residue, mostly plastics and derivatives, can be processed further in other recycling methods.

Enhanced Recovery: Innovations by Henan Terbaik Machinery have minimized leaks during the physical process, improving the efficiency and effectiveness of metal recovery.

Henan Terbaik Machinery offers advanced shaking tables that address the needs of both the mining and recycling industries. With their innovative designs and commitment to zero loss, they ensure high recovery rates and purity of precious metals. The company's tables incorporate both physical and chemical solutions, meeting customer needs with a vision of zero loss.

In summary, shaking tables are indispensable in the e-waste recycling industry for their ability to separate valuable metals from other materials efficiently. With features that enhance fine material recovery and a robust design, they offer a reliable solution for both mining and recycling applications.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

A shaking table is a rectangular-shaped table with ribbed decks over which a water film flows. Here’s how it works:

Sample Feeding: The sample is fed onto the table, and water flows along the long axis, creating a slurry.

Particle Transport: Low-density particles are carried by the fast-moving water film, while fine, high-density particles settle into the beds behind the riffles.

Table Movement: The table moves rapidly backward, causing particles to gain forward momentum. This motion helps separate the different particle structures.

Separation Process: The separation performance is closely related to the particle size distribution; narrower grain sizes lead to better separation.

Key Points:

Ribbed Decks: These decks help channel the water film and particles along the table.

Water Film: Essential for creating the slurry and moving particles according to their densities.

Momentum: The backward and forward motion separates particles based on their density and size.

Wilfley Tables: Used widely for recovering precious metals in gold mines.

Gemini Tables: Commonly used in electronic waste recycling processes.

Shaking tables are particularly effective for the recovery of precious metals and are essential in both mining and recycling industries for their efficient separation capabilities based on particle density and size.

As an OEM & ODM in gold recovery equipment with rich experience and numerous Independent Intellectual Property Rights, Henan Terbaik Mine Machinery provides various models of mini gold dredges with different dimensions and capacities. Here is a list of our hottest models. For more specific parameters, please contact us directly.

*The output will vary according to different materials, feed particle size and other factors