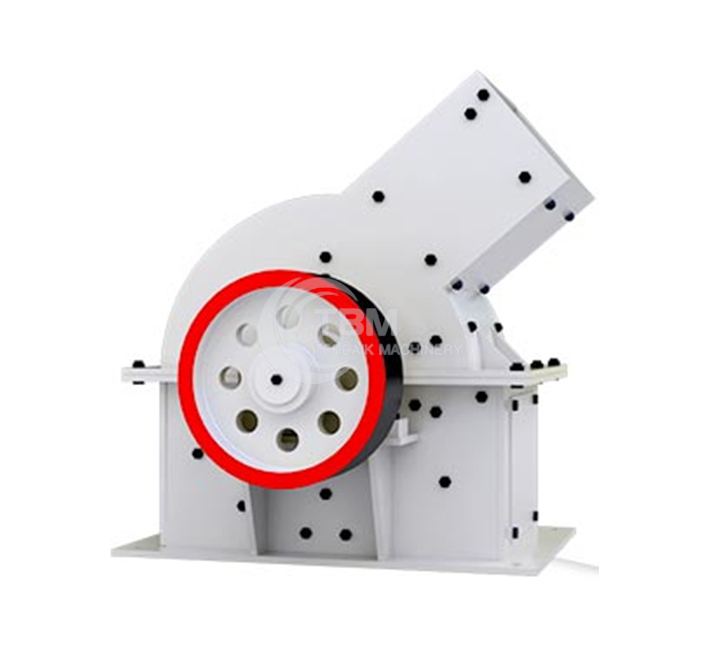

Terbaikmachinery offers Rock Hammer Crushers for robust crushing solutions in various industries. Our Rock Hammer Crushers ensure efficient material crushing, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted crushing solutions that deliver superior results and optimize your mining material processing operations.

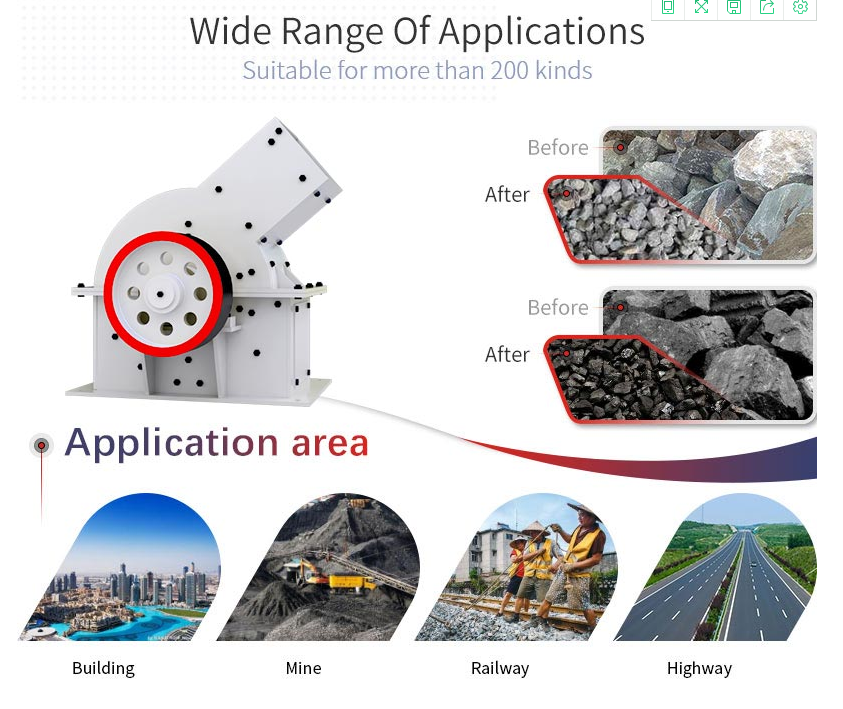

Types of hammer mill is mainly used for crushing medium-hard or brittle materials with hardness not more than 300Mpa and 15% moisture,such as coal, cement,gypsum,alumen,brick,tile,limestone,etc.It has the features of simple structure, big crushing ratio, high production efficiency, uniform particle size, etc. This equipment can be adjusted to reach various discharged granularity as the customers' requests.

Hammer crusher is the most common of stone crushing equipment. It is also called hammer mill. It has high production capacity, low energy consumption, simple structure, reliable quality, easy maintenance, etc.

Eccentric shaft adopt 40Cr steel precise forged, Advanced Movable jaw plate assemble made from high quality casting parts, Tooth-shape plate, deep V-chamber, high manganese steel material ZGMn13-4 make crusher more reliable, Precise casting heavy fly wheel,Jaw crusher frame adopt thick Q235B heavy steel plate welding process.Machine blasting, anti-rust painting, surface painting at least three times paintings.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

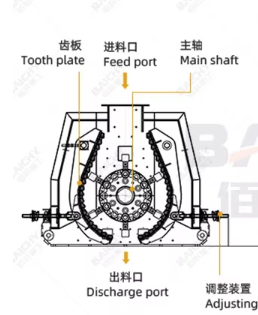

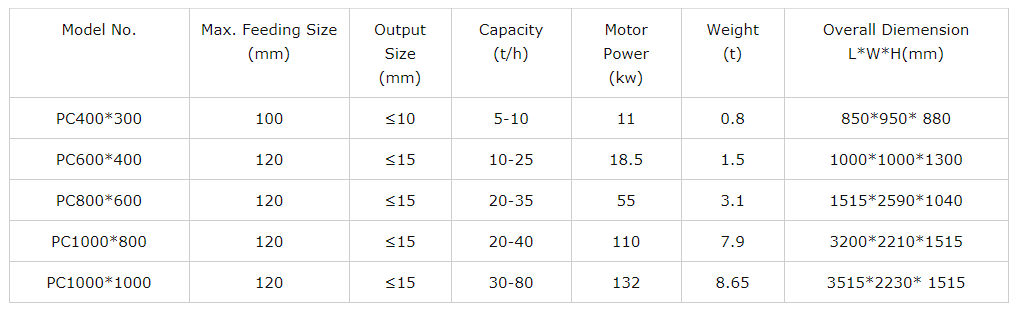

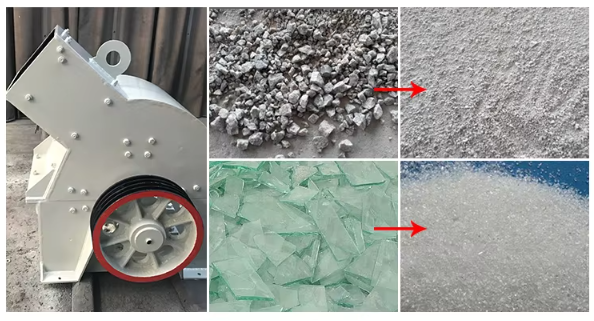

Motor drives the rotor quickly in the crushing cavity. Raw materials enter the crusher through the feeding inlet and are impacted, cut and ground by high-speed hammer heads. There is a grate under the rotor assemblly, so that materials with size smaller than the grate mesh will be screened out and others are left to be further hammered until they reach the standard size. The size of the final product can be adjusted by changing the grate, the gap between the rotor assemblly and the grate can also be adjusted according to different requirements.

Soft hard rock and middle hard stone, such as soapstone, gypsum, calcite, fluorite, limestone, shell, glass etc

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors