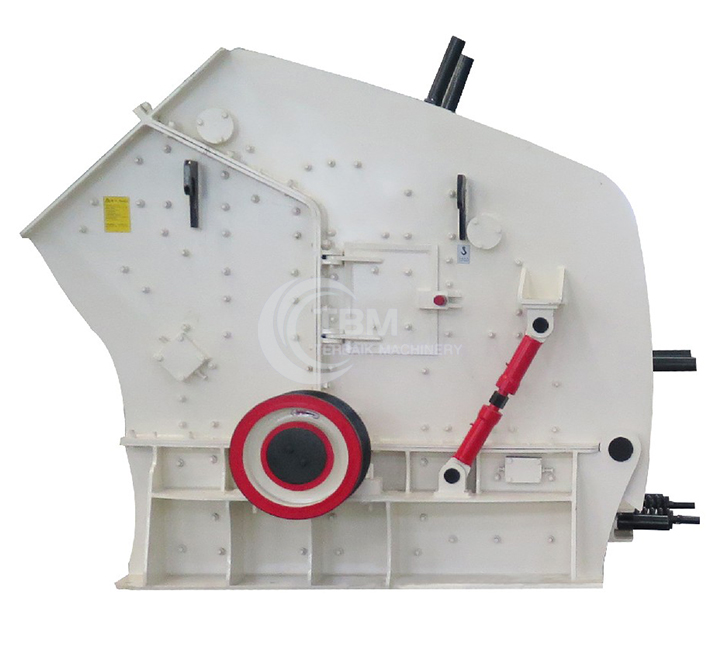

Terbaikmachinery offers Impact Crushers for powerful crushing solutions in various industries. Our Impact Crushers ensure efficient material crushing, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted crushing solutions that deliver superior results and optimize your material processing operations.

PF series impact crusher is a mechanical equipment that uses the high-speed impact principle for crushing. It is mainly used for medium and fine crushing of various medium-hard materials with compressive strength not higher than 100MPa, such as limestone, clinker, slag, coke, coal, etc.

PF series impact crusher has a variety of models to choose from. Different models of crushers have differences in rotor size, processing capacity, power consumption, etc. It is an efficient, energy-saving, and durable crushing equipment.

Hot-selling Models of PF Series Impact Crusher

PF1315, PF1214, and PF1210 impact crushers perform well in processing medium-hard materials, with high crushing efficiency and large crushing ratio. The product shape is mostly cubic, with the advantage of selective crushing, and the discharge particle size is adjustable, simplifying the process.

PF1010 and PF1007 may have slightly lower processing capacity, but users still favor their compact structure, flexible layout, and low investment cost in some occasions where the output requirements are not particularly high.

Advantages of PF Series Impact Crusher

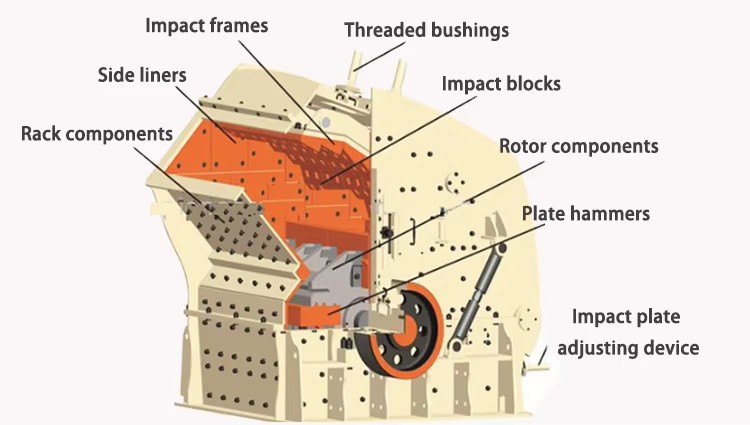

Multi-cavity uniform crushing: suitable for crushing hard rock and other materials with high compressive strength, with a uniform crushing effect.

Low and large feed port: convenient for production line layout and increasing feed size, improving production efficiency.

Fully hydraulic opening: convenient for repair and replacement of wearing parts, reducing maintenance costs.

New wear-resistant materials: key components such as hammer, impact liner, and liner are made of new wear-resistant materials, with longer service life.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

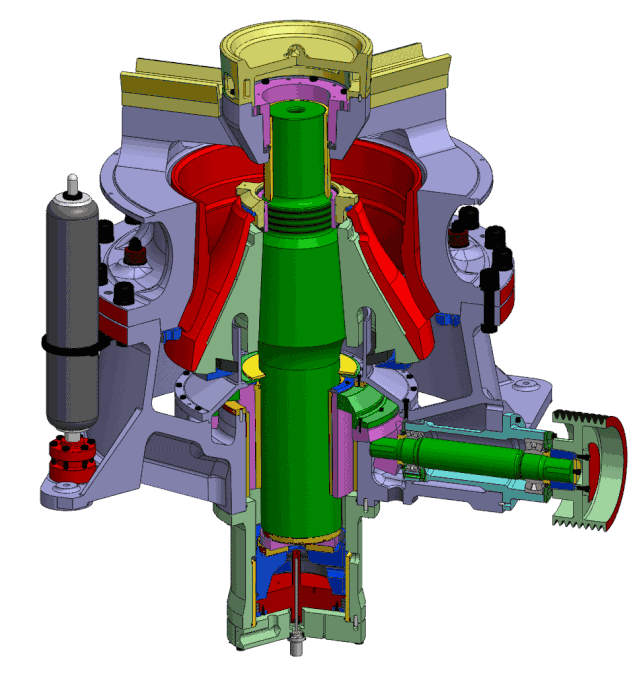

When the impact crusher is working, the motor drives the rotor through the V-belt, and the material is crushed by the high-speed impact of the hammer on the rotor, and is thrown to the impact bracket to break again, and then bounce from the impact surface to the impact area of the hammer again. Crushing, this process is repeated until the material is crushed to the required size. The material flows from the first feed port to the first crushing chamber, and then into the second crushing chamber. When the crushed ore particle size is smaller than the gap between the hammer head and the impact plate, it will be discharged from the lower part of the machine, which is the crushed ore. product. This machine adopts a self-weight safety device on the rear rack. When the non-broken objects enter the crushing chamber, the front and rear counter-attack frames will retreat, and the non-broken objects will be discharged from the machine body.

The rotor is mostly made of integral cast steel, with a strong and durable structure and easy-to-install plate hammer. It has a large mass and can meet the crushing requirements. The rotor of small and light impact crushers can also be welded from steel plates.

Plate hammers are generally made of high-chromium cast iron, high-manganese steel, and other wear-resistant alloy steels, with various shapes, such as long strips, T-shaped, S-shaped, etc. The design should meet the requirements of reliable operation, easy loading and unloading, and improved metal utilization of plate hammers.

The liner is cast with a multi-element alloy based on ZGMn13-2, and appropriate amounts of Mo, Ni, Ti, and other elements are added to the alloy to ensure its high wear resistance, good toughness, and impact resistance.

| Model | Specification (mm) | Feed opening (mm) | The Maximum Feeding Size (mm) | Capacity (t/h) | Power (kw) | Total weight (t) | Overall dimension (L×W×H) (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 12 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-66 | 15 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 17.7 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 100-180 | 6P 132 | 22.4 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 130-250 | 6P 200 | 27 | 3180×2720×2620 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 165-320 | 6P 250 | 34 | 3220×3100×2620 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 300-550 | 4P 315-400 | 50.6 | 3959×3564×3330 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 600-800 | 6P 630-710 | 83.21 | 4400×3866×4 |

About delivery standards

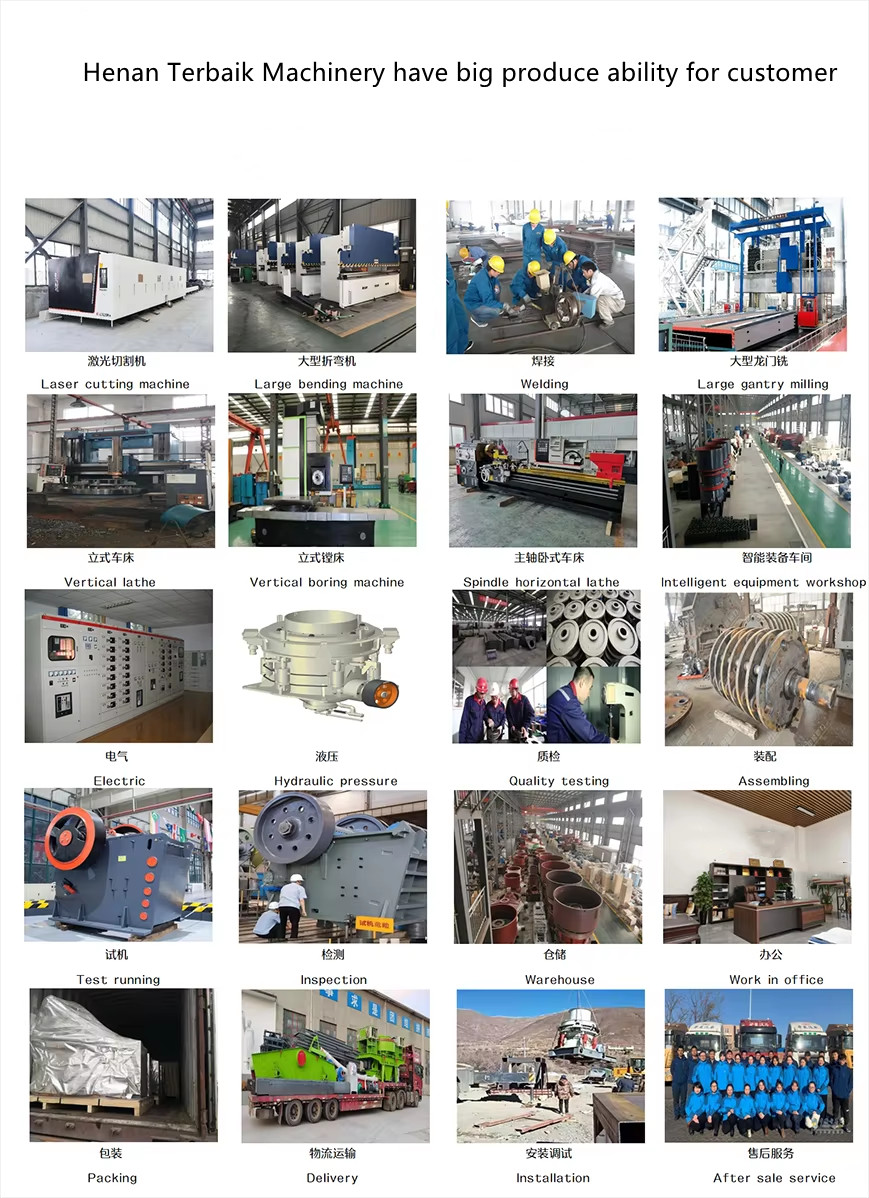

Terbaik machinery has extremely complete delivery standards, a series of standards and regulations formulated to ensure that the ordered goods can be delivered completely and accurately according to the needs and requirements of customers. These standards usually involve quantity, specifications, quality, packaging, documents and time, etc., to ensure the smooth progress of the delivery process and improve customer satisfaction.

*The output will vary according to different materials, feed particle size and other factors