Rotary Trommel sieves Usage and application:The Rotary Trommel sieves machine is a new type of self-cleaning material-screening special equipment. It is widely used in screening various solid materials that size less than 300mm.The rotary screening machine is suitable for dry production of machine-m

Rotary Trommel sieves Usage and application:

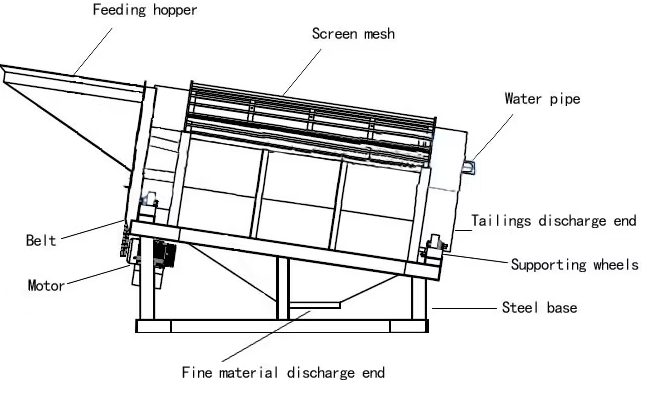

The Rotary Trommel sieves machine is a new type of self-cleaning material-screening special equipment. It is widely used in screening various solid materials that size less than 300mm.

The rotary screening machine is suitable for dry production of machine-made sand, and can also be used for granular wet material tower screening machine. It is composed of several circular screens, so it is also called a basket screen. The whole is at a height above the ground, and the outside is sealed by a sealed isolation cover to prevent environmental pollution.

Rotary Trommel sieves Features

According to different grading requirements, the grading levels of the drum screen are generally 1-4 sections from fine to coarse. The materials are screened from the first section to the last section of the screen from fine to coarse, and the materials larger than the holes of the last section of the screen are discharged from the discharge port.

During use, the drum screen runs slowly and evenly, with little impact vibration, stable operation, simple installation, and sometimes even no special foundation is required. It can be placed directly on a flat ground or floor and under the silo. The machine is easy to seal and collect dust, has a small amount of maintenance, simple maintenance, and a long service life. It is a frequently used equipment in the grading of refractory materials, coal, river sand, and sand and gravel blocks.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Rotary Trommel sieves work principle

The drum device is installed obliquely on the frame. The electric motor is connected to the drum device through a coupling via a reducer, driving the drum device to rotate around its axis. After the material enters the drum device, due to the tilt and rotation of the drum device, the material on the screen surface flips and rolls, causing qualified materials (undersized products) to be discharged through the discharge port at the bottom of the rear end of the drum, and unqualified materials (undersized products) to be discharged through the discharge port at the tail end of the drum. Due to the flipping and rolling of materials inside the drum, materials stuck in the sieve holes can be ejected to prevent blockage of the sieve holes. The principle and structure of drum sand screening machine, drum screening machine and drum screen are almost the same, but there are differences in people's understanding and naming of them.

Rotary Trommel sieves technical parameters

*The output will vary according to different materials, feed particle size and other factors