Terbaikmachinery offers VSI Sand Making Machines for advanced material creation in mining industries. Our VSI sand making machines ensure efficient sand production, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted material creation solutions that deliver superior results and optimize your sand processing operations.

Vertical Shaft Impact Crusher is a new type of sand-making machine with the advantages of high efficiency, energy saving, and environmental protection. It is mainly used to crush various raw materials (such as river pebbles, limestone, iron ore, etc.) and plastically shape them into the required artificial sand.

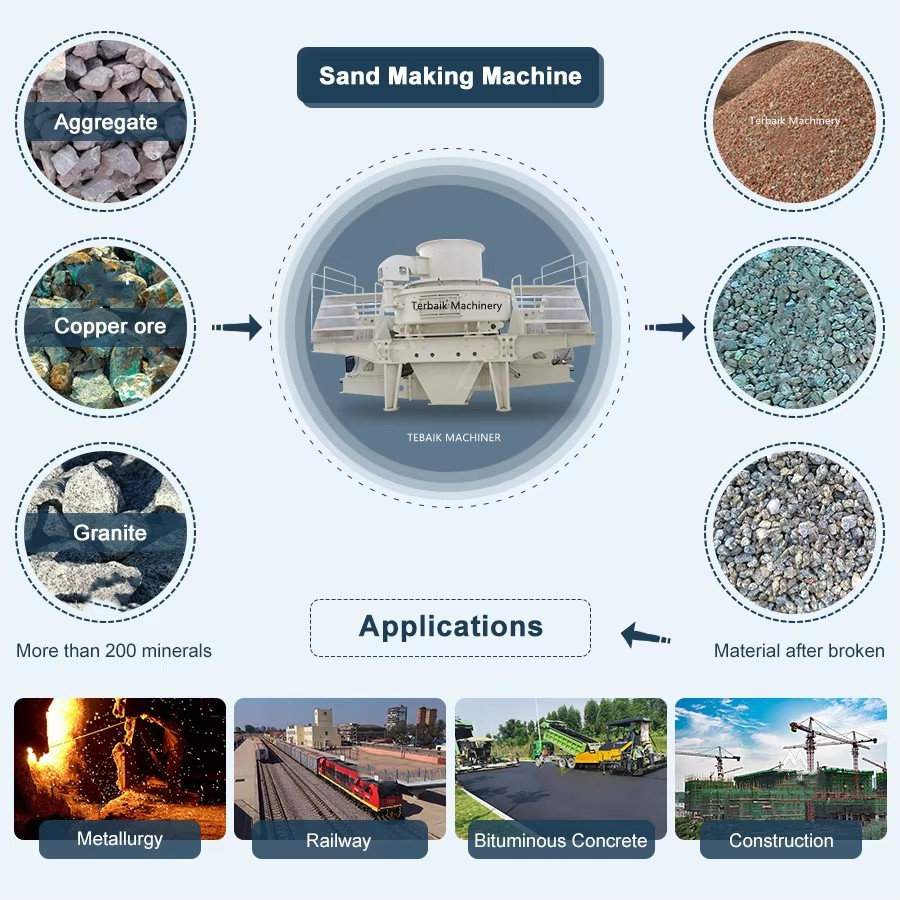

VSI sand-making machine is suitable for handling a variety of materials, including rock materials (such as river pebbles, granite, basalt, limestone, quartz, etc.), ore materials (such as iron ore, copper ore, etc.), and other materials (such as coal gangue, construction waste, steel slag, etc.).

VSI sand-making machine uses the impact force between the high-speed rotating rotor and the feed material to crush the material, and plastically shape it through the friction and wear between the materials. The sand produced has uniform particle size, perfect shape, and stable quality, especially suitable for materials with higher hardness.

Vertical Shaft Impact Crusher uses high-speed rotating materials to crush each other and the friction between materials to crush (stone hitting stone). The maximum particle size of the feed is generally not more than 60mm. In the production process, a VSI sand-making machine is usually used as the second or third process, in conjunction with a jaw crusher or impact crusher.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

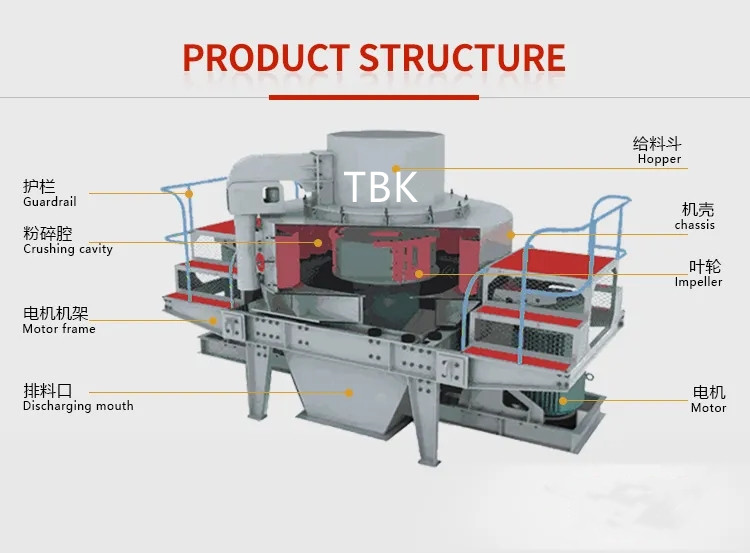

The sand-making machine is composed of seven parts: a feeding hopper, a distributor, a vortex crushing chamber, an impeller body, a main shaft assembly, a base, a transmission device, and a motor.

The material falls vertically into the high-speed rotating impeller from the upper part of the machine. Under the action of high-speed centrifugal force, it will collide with another part of the material shunted around the impeller in the form of an umbrella. The material forms a vortex between the casings, collides and rubs each other many times, is crushed, and is directly discharged from the lower part to form a closed circuit for multiple cycles. After being controlled by the screening equipment, the finished product reaches the required particle size.

The main function of sand sand-making machine is to crush materials of various hardness (such as river pebbles, mountain rocks, ore tailings, etc.) and shape them into sand and gravel aggregates that meet the requirements. These sand and gravel products are widely used in many fields such as construction, roads, railways, water conservancy, chemical industry, etc.

In the sand production line, the sand-making machine is usually located after the coarse crushing and medium crushing and is used as fine crushing equipment for further crushing to ensure that the material reaches the required particle size.

The sand-making machine can accurately control the particle size of the output material to meet the specific requirements of different projects for the particle size of sand and gravel. For example, new sand-making machines (such as vertical shaft impact crushers) have a particle size adjustment device, which can easily adjust the fineness of the output material.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

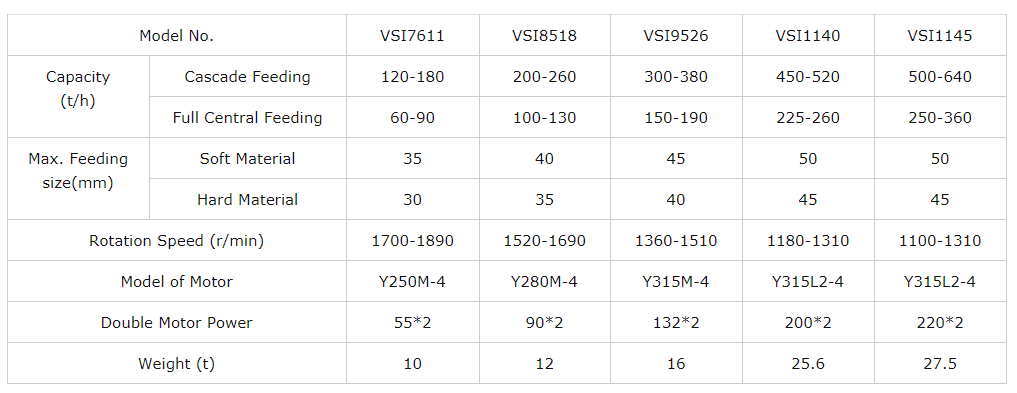

*The output will vary according to different materials, feed particle size and other factors