.jpg)

The Wood Chip Dryer is an advanced drying machine designed for efficiently drying wood chips, sawdust, wood powder, and shavings. With high thermal efficiency, rapid drying capability, and a compact design, it provides an ideal solution for industries needing large-scale wood drying and dehumidification.

The Wood Chip Dryer is a specialized drying machine designed specifically for drying materials such as wood chips, sawdust, wood powder, and wood shavings. Known for its high drying capacity and energy-saving performance, it utilizes a screw conveyor to continuously feed the material into the drying pipe. The high-speed hot airflow disperses the wet material, evaporating moisture to yield powdery or granular dried products. Key components include an air heater, feeder, airflow drying pipe, cyclone separator, and fan.

The image above shows a field application of our wood chip drying equipment, processing sawdust. This equipment is highly suitable for drying and dehumidifying wood-based materials like wood chips, wood dust, and wood powder, delivering large production volumes and high efficiency.

.jpg)

Short Drying Time: The dryer rapidly reduces moisture content for optimal efficiency.

Compact and Simple Structure: The streamlined design requires minimal space, making it easy to construct and maintain.

High Drying Intensity: Due to the high dispersion of materials in the airflow, the entire particle surface is fully exposed, maximizing effective drying area.

Large Processing Capacity and High Thermal Efficiency: When drying non-bound water, thermal efficiency can reach up to 60%.

.jpg)

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The wood chip dryer consists of a heat generator, feed inlet, rotating drum, filter drum, material conveyance pipe, cooling drum, and discharge outlet. Positioned on a driving roller, the rotating drum operates at a low speed, driven by a motor and reducer. The heat generator is connected to the rotating drum via the feed inlet, with stirring blades inside the drum to agitate the material. At the connection point between the rotating and filter drums, a baffle with a small opening is installed. The filter drum connects the rotating drum with the material transport pipe, and it contains baffles and a bottom slag discharge hole. One end of the cooling drum connects to the material pipe via a blower, while the other end links to the discharge outlet.

With this design, wood chips are fully dried inside the rotating drum, and further dispersed before entering the material pipe, which accelerates moisture evaporation. The baffles effectively block impurities, ensuring the quality of the wood chips that proceed through the transport pipe. Inside the wood chip dryer, the hot air and rotating drum cause the material to fluidize, ensuring thorough contact with the hot air for efficient drying.

.jpg)

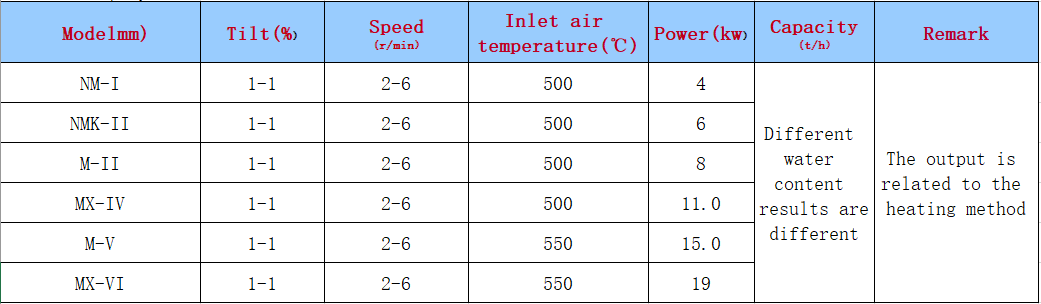

*The output will vary according to different materials, feed particle size and other factors