Terbaikmachinery's XS Series Sand Washers provide efficient solutions for sand washing needs. With advanced technology and reliable performance, our sand washing machines ensure thorough cleaning of sand particles, enhancing the quality of your materials. Trust Terbaikmachinery for expertly crafted sand washers that deliver optimal results and maintain the integrity of your materials.

What is a wheel sand washer?

Wheel sand washer is a mechanical device specially used for cleaning sand and gravel. It mainly removes dirt, dust, and other impurities in sand and gravel through the combined action of mechanical force (such as impeller rotation) and water flow, thereby improving the cleanliness and quality of sand and gravel.

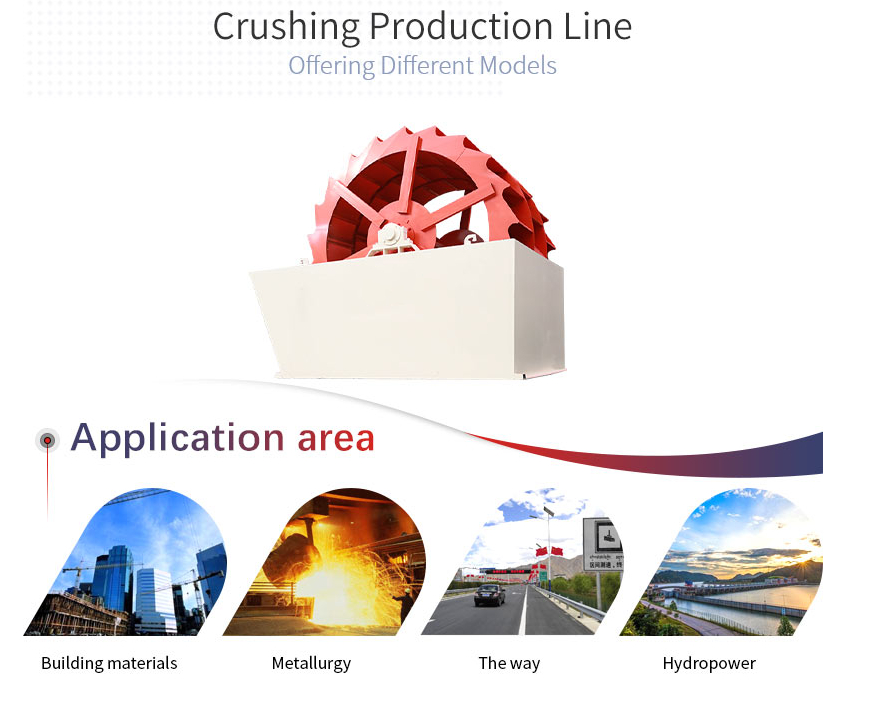

Bucket wheel sand washing machine application scenarios

Gravel material washing: Bucket wheel sand washing machine plays an important role in the gravel field. It is used to clean and separate the mined gravel, remove impurities such as soil and stone powder on the surface, and improve the quality of gravel.

Improve the value of gravel: Through cleaning, gravel can be made cleaner, meeting the demand for high-quality gravel in industries such as construction and road paving, thereby improving the market value of gravel.

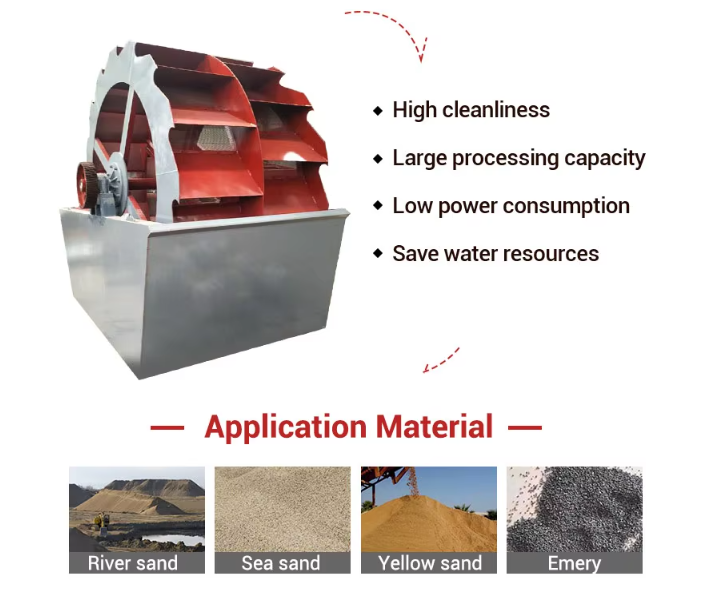

Advantages of wheel sand washer

High cleaning degree, large processing capacity, low power consumption, low failure rate, etc. It is widely used in construction, roads, railways, water conservancy, concrete mixing stations, and other industries, providing these industries with high-quality sand and gravel raw materials.

Environmental protection of wheel sand washer

The wheel sand washer also has certain environmental protection performance. During the cleaning process, it can effectively reduce the emission of dust and wastewater and reduce pollution to the environment. At the same time, through reasonable equipment design and operation management, it can also realize the recycling of water resources and improve resource utilization efficiency.

Bucket wheel sand washing machine application scenarios

Gravel material washing: Bucket wheel sand washing machine plays an important role in the gravel field. It is used to clean and separate the mined gravel, remove impurities such as soil and stone powder on the surface, and improve the quality of gravel.

Improve the value of gravel: Through cleaning, gravel can be made cleaner, meeting the demand for high-quality gravel in industries such as construction and road paving, thereby improving the market value of gravel.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

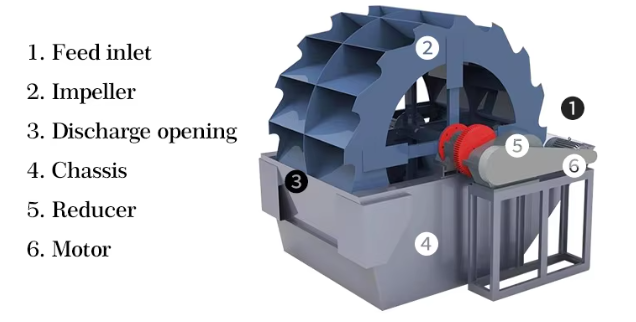

What Is The Working Principle Of The Wheel Sand Washing Machine

When the wheel-type sand washing machine is working, the motor drives the impeller to rotate slowly after being decelerated by the V-belt, the reducer, and the gear. At the same time, add water to form a strong water flow, take away impurities and foreign matter with a small specific gravity in time, and discharge them from the washing tank at the overflow port to complete the cleaning function. The clean gravel is taken away by the blades and poured into the discharge chute from the rotating impeller to complete the cleaning of the gravel.

Maintenance of wheel sand washer

In order to keep the wheel bucket sand washer in good operating condition, regular maintenance and maintenance are required. It mainly includes checking the wear of the bearings, cleaning the debris inside the equipment, and replacing severely worn parts. At the same time, attention should also be paid to the lubrication and sealing of the equipment to ensure efficient and stable operation of the equipment.

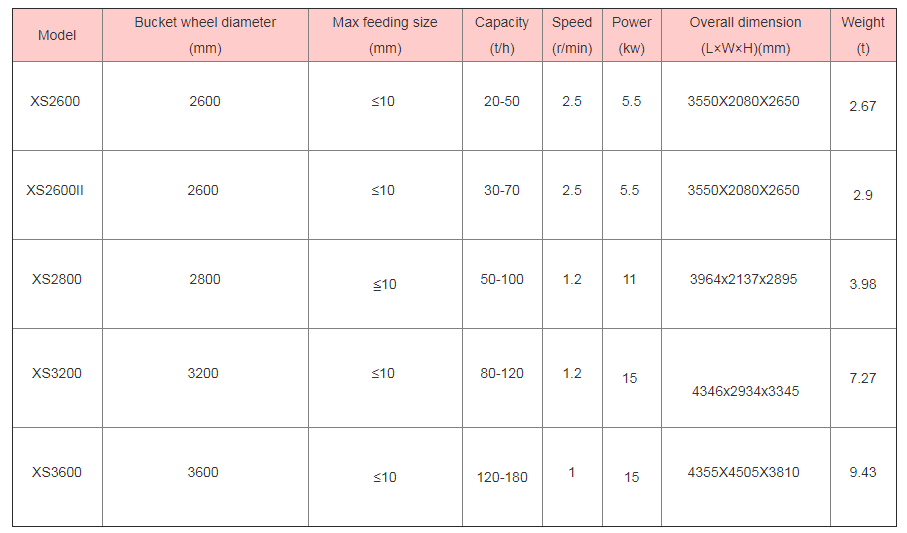

What is the processing capacity of a Wheel sand washer?

The production capacity of a wheel sand washer is roughly between 20-250 tons/hour. Of course, the actual processing capacity is also affected by the following factors:

1. Equipment model and specifications: Different models of bucket wheel sand washers have different power, speed, impeller diameter, tank size, etc., which directly affect the processing capacity of the equipment. Generally speaking, large wheel sand washers have relatively large processing capacity.

2. Raw material characteristics: The particle size, humidity, mud content, and other characteristics of the raw materials will also affect the processing capacity of the wheel sand washer. For example, raw materials with small particle sizes, high humidity, and high mud content may reduce the processing efficiency of the equipment.

3. Working time: Under the same conditions, the longer the working time, the greater the processing capacity of the wheel sand washer. However, it should be noted that long-term continuous work will cause certain wear and tear on the equipment, so it is necessary to arrange the working time and equipment maintenance plan reasonably.

FAQ:

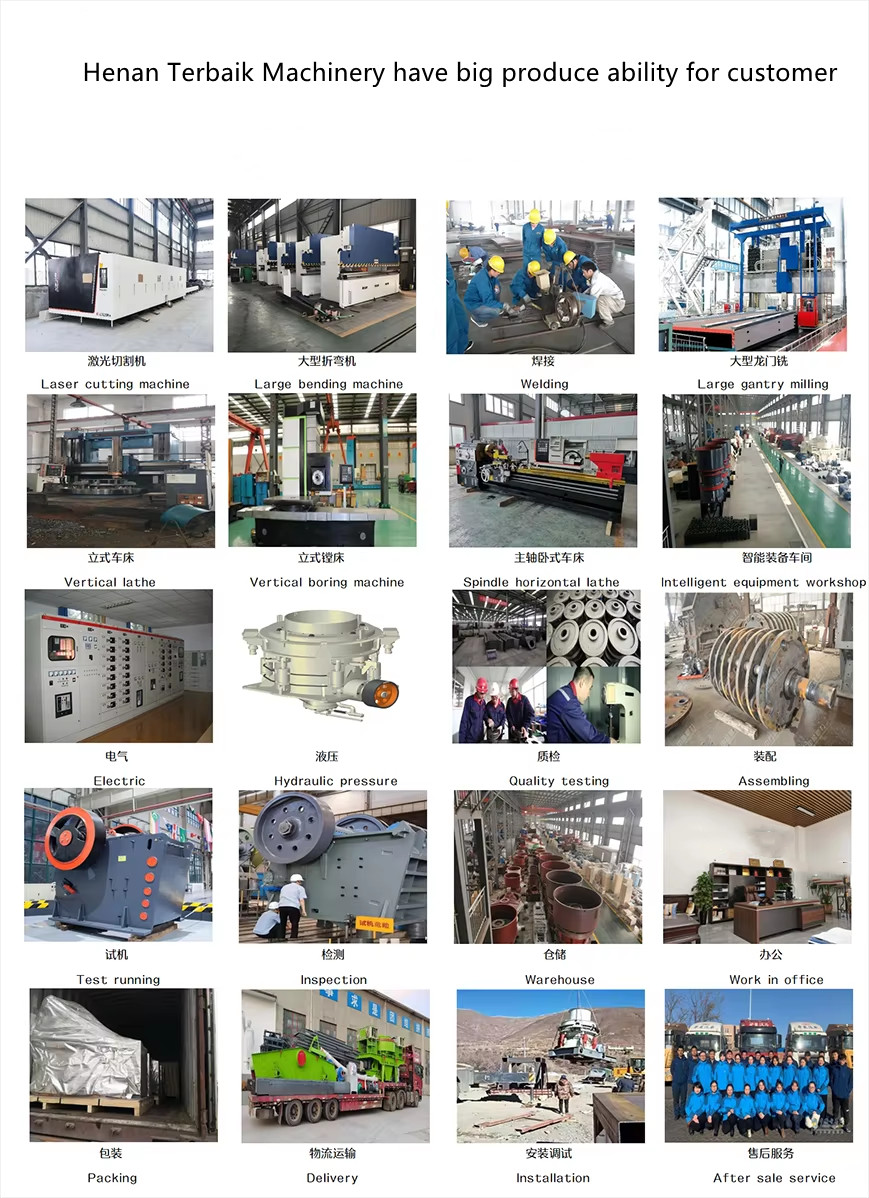

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors