Mobile Gold Processing Washing Plant Equipment from Terbaik Machinery.High Quality Wash Plant For Gold Mining Mobile Gold Processing Washing Plant Equipment For Washing Gold

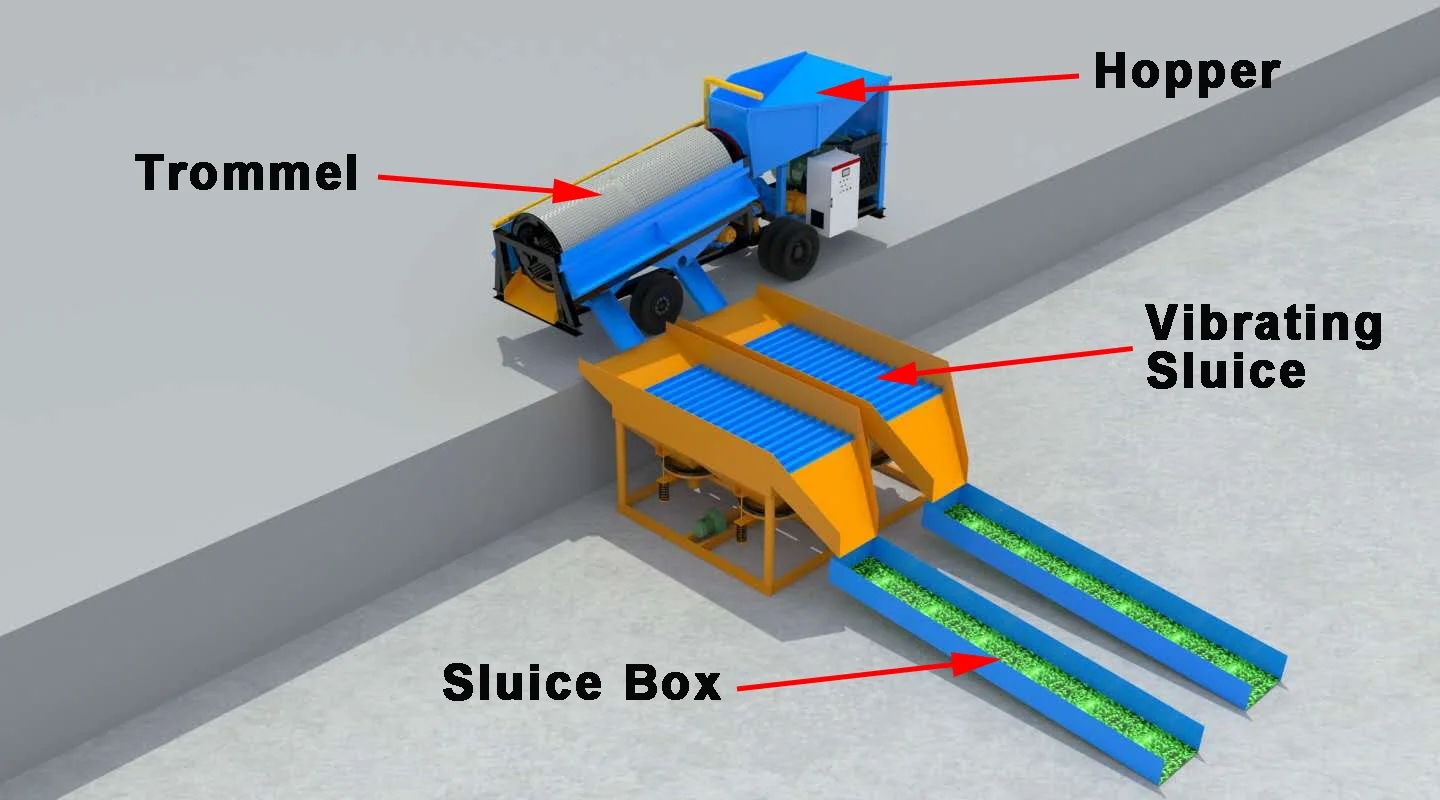

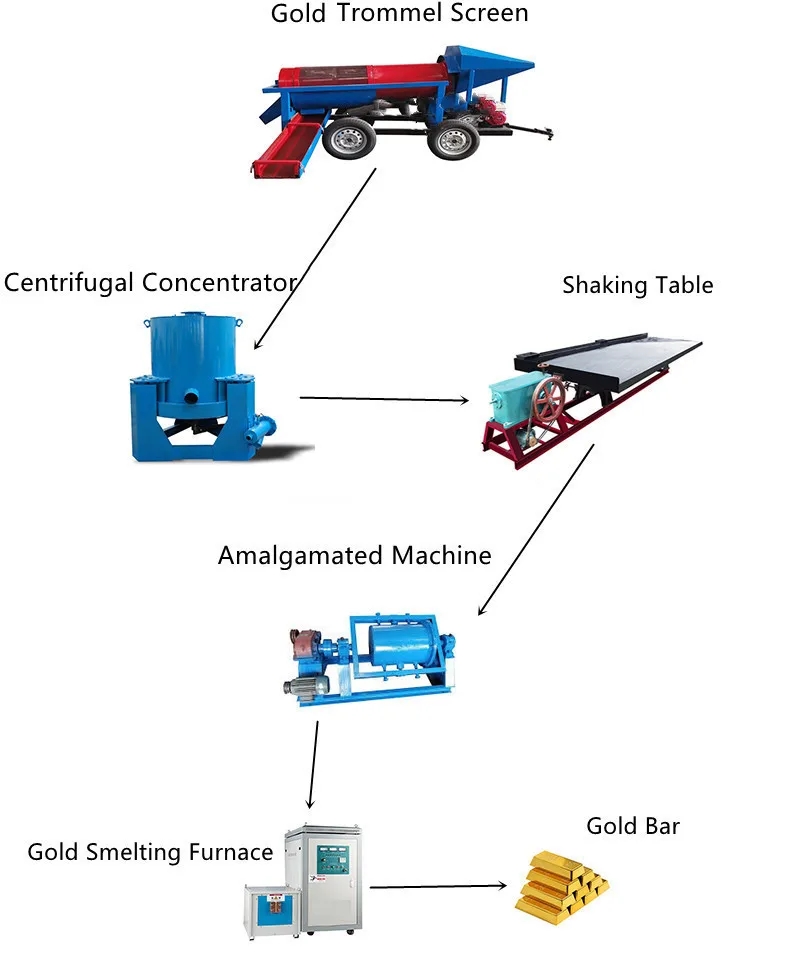

The Mobile Gold Processing Washing Plant Equipment consists of a hopper, trommel, chassis, tires, turntable, generator, water pump, gearing, control panel, and gold recovery sluice. This optimized, removable platform is designed for gold recovery and is ideal for small to medium-scale placer gold ore processing that requires mobile operations. It is also suitable for placer gold, alluvial gold, alluvial diamond mining, river sand gold/diamond mining, and deposit clay gold/diamond mining.

Mobile gold processing washing plant equipment is essential in the mining industry, particularly for small to medium-sized operations. Here are the key applications:

Alluvial Gold Mining:

Mobile gold processing plants are extensively used in alluvial gold mining operations. They are designed to process placer deposits where gold is found in loose sedimentary materials like sand, gravel, and clay. These plants wash and separate the gold from other materials, making them highly effective for extracting gold from alluvial deposits.

Hard Rock Mining:

Mobile gold processing plants can also be used in hard rock mining. These plants can crush and process ore directly at the mining site, eliminating the need for transporting ore to a central processing facility. This is particularly useful in remote locations where transportation infrastructure is limited.

Artisanal and Small-Scale Mining (ASM):

Mobile gold processing plants are widely used by artisanal and small-scale miners. These plants are typically more affordable and easier to operate than large, stationary processing plants. They provide a viable option for small-scale miners to process their gold efficiently and with relatively low capital investment.

Environmental Remediation:

Mobile gold processing equipment can be used in environmental remediation projects. These plants can help recover gold from contaminated soils, sediments, and other materials, contributing to the clean-up of polluted areas while extracting valuable resources.

Temporary Mining Operations:

In situations where mining operations are temporary or seasonal, mobile gold processing plants offer a flexible solution. They can be easily transported to different sites as needed, allowing for efficient processing without the need for permanent infrastructure.

Overall, mobile gold processing washing plant equipment provides a versatile, efficient, and cost-effective solution for various gold mining applications, from small-scale operations to exploration and environmental remediation.

Mobile Gold Processing Washing Plant is a product developed by Henan Terbaikmachinery according to the extraction of sand gold, belongs to the mobile gold panning machinery, two outputs for the screening equipment and the pump system to provide power, for the integration of integrated gold panning equipment. The Equipment operation is simple, easy to move and large handling capacity

Mobile gold processing washing plant equipment offers several advantages, making it an attractive option for various mining operations.

Portability and Flexibility: Mobile plants can be easily transported to different locations, allowing miners to move them as needed. This flexibility is particularly useful in remote or inaccessible areas where building permanent infrastructure is challenging.Easy to move, integrated design, adapt to the complex terrain in the field.

Cost Efficiency: Mobile plants typically require lower capital investment compared to stationary processing plants. They eliminate the need for expensive transportation of raw materials to a central processing facility, reducing overall operational costs.Large capacity, high recovery rate.

Quick Setup and Deployment: Mobile gold processing plants can be quickly set up and made operational. This is advantageous for short-term or temporary mining projects where time is a critical factor.Simple operation, 2 workers can operate, saving costs for customers.

Versatility: These plants are designed to handle a variety of gold-bearing materials, including alluvial deposits, hard rock ores, and tailings. This versatility makes them suitable for different mining scenarios.Many mobile plants are modular and customizable, allowing miners to tailor the equipment to their specific needs and easily upgrade or modify the system as required.

Efficient Recovery: Modern mobile gold processing plants are equipped with advanced recovery systems, ensuring high efficiency in gold extraction and reducing losses.The use of construction machinery feeding, high efficiency. Mobile plants do not require extensive infrastructure development, such as permanent buildings or large power supplies, making them ideal for remote and underdeveloped regions.

Overall, the advantages of mobile gold processing washing plant equipment make it a valuable solution for a wide range of gold mining operations, offering efficiency, flexibility, and cost-effectiveness.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

1. Dry Gold Mining

Setup and Mobility:

The dryland Mobile Gold Processing Washing Plant Equipment features rubble tires, making it easy to move across various terrains such as ancient riverbeds and dry beach sand.

Components and Function:

Typically, these plants use a trommel screen combined with a small gold jig and sluice box to form a single mobile gold recovery unit. This setup effectively processes placer gold and monomer lode gold.

Advantages:

These small-scale gold wash plants are lightweight, easy to maintain, and low-cost, making them suitable for dryland gold mining.

2. River Gold Mining

Mobile Gold Processing Washing Plant Equipment often takes the form of a multifunctional gold dredging ship that floats on water. These ships combine excavation, ore washing, beneficiation, tailings disposal, and provide both power and water supply.

Processing Steps:

Raw Material Feeding:

Raw materials are fed through the hopper inlet and pushed into the screen drum by powerful water pressure from a nozzle loaded in the hopper.

Washing:

The screen barrel, equipped with a built-in galvanized seamless water spray pipe (diameter 42mm), washes the raw materials. The materials are then selected through the gold panning tank as the trommel screen rotates.

Fine Gold Collection:

Light dirt and sand are washed away by the water, while heavier gold particles gather in the gold blanket for collection.

This comprehensive approach ensures efficient gold recovery from both dryland and river environments, leveraging the specific advantages of each type of mobile gold wash plant.

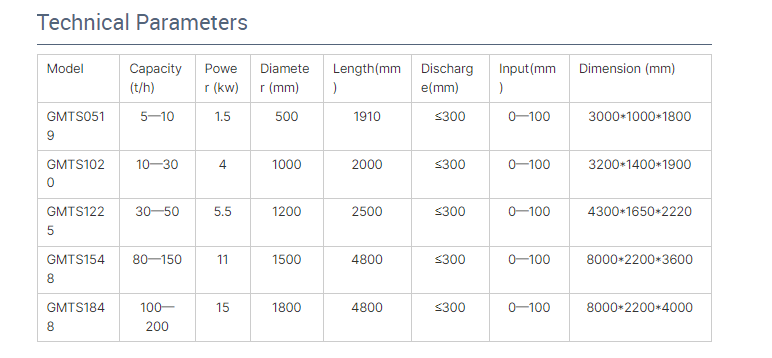

*The output will vary according to different materials, feed particle size and other factors