Terbaikmachinery offers high-quality agitator tanks designed for efficient mixing solutions in various industrial applications. Our industrial-grade tank mixers are engineered to ensure thorough agitation and homogenization of liquids, enhancing chemical processing and material mixing operations. Trust Terbaikmachinery for expertly crafted agitation solutions that deliver optimal performance and reliability.

Introduction

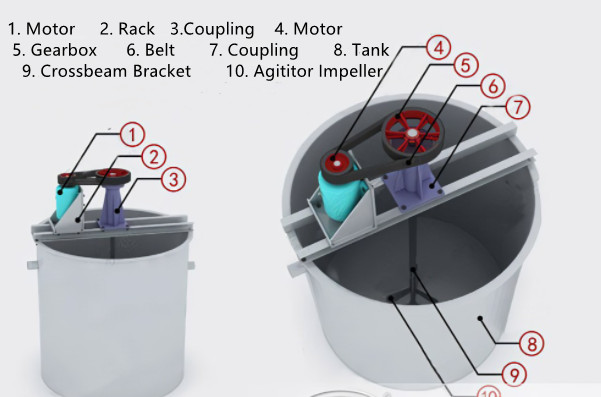

The high-efficiency agitator tank is designed to force the slurry to circulate up and down, ensuring thorough mixing of reagents and slurry. This improves the effectiveness of the chemical reactions involved in the process.

Improvement

This tank features an umbrella-shaped impeller that presses the slurry, creating an up-and-down circulation along the draft tube. This design ensures that reagents and slurry mix well, optimizing the reaction process.

Agitator Tank Features

The agitator tank, also known as a mixing barrel, is essential equipment in mineral processing and various chemical industries. It is driven by a V-belt connected to an electric motor, which rotates the impeller to mix the reagents and slurry fully and evenly. This thorough mixing increases the reaction time of the reagents, enhancing the quality and efficiency of the chemical reactions.

V-Belt Drive: An electric motor drives the impeller via a V-belt, ensuring efficient power transmission and reliable operation.

Enhanced Mixing: The up-and-down circulation promoted by the umbrella-shaped impeller ensures thorough mixing, increasing the reaction time and improving reaction quality.

Versatility: Suitable for mineral processing and various chemical industries, making it a versatile piece of equipment.

Applications

Mineral Processing: Ensures optimal mixing of slurry and reagents for effective mineral separation and processing.

Chemical Industries: Used for agitation in various chemical processes, ensuring uniform mixing and improved reaction efficiency.

The high-efficiency agitator tank enhances the mixing process by creating thorough up-and-down circulation of the slurry, thanks to its umbrella-shaped impeller. This design, driven by an electric motor via a V-belt, ensures even mixing, increased reaction time, and improved reaction quality, making it indispensable in mineral processing and chemical industries.

Compact Structure: The agitator tank has a compact design with good sealing and is equipped with an ash baffle at the feed inlet to prevent water mist from backflowing.

Even Stirring: Features fan-shaped stirring blades that ensure a large contact area with the medium during stirring for uniform mixing.

Multi-Row Nozzles: Equipped with multiple rows of nozzles that provide a uniform and adjustable water volume.

Low Residual Ash Rate: The watershed design at the bottom of the tank ensures there are no dead corners inside the equipment, reducing residual ash.

Advanced Performance: The mining mixing drum equipment delivers advanced performance, stable product quality, uniform mixing, and fast discharge.

Additional Features

Strong Stirring Ability: The impeller has an advanced structure with a strong stirring ability.

Umbrella-Shaped Impeller: The Terbaik high-efficiency agitation tank features an umbrella-shaped impeller with a large diameter and high linear velocity, enhancing agitation and circulation capability.

Improved Flotation Index: Enhanced circulation capability leads to better flotation index.

Efficient Suction Capability: The baffle design compresses negative pressure into a limited space, improving suction capability and thus enhancing the overall circulation capacity.

The agitator tank is designed for optimal mixing performance with features that ensure compact structure, effective sealing, and efficient stirring. The fan-shaped stirring blades, multi-row nozzles, and advanced impeller design contribute to uniform mixing, low residual ash rates, and enhanced circulation and flotation capabilities. These features make the agitator tank highly effective in various industrial applications, including mining, chemical processing, and more.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The agitator tank, also known as the mixing barrel, is suitable for various metal ores and is mainly used for stirring before flotation to ensure that the reagents are fully mixed with the ore pulp. Additionally, it can be used for stirring other non-metallic minerals. It is designed for concentrations not exceeding 30% by weight and fixed components with particle sizes of less than 1mm. The tank is characterized by its flat-bottomed, barrel-shaped design with a radial circulation spiral impeller for mechanical stirring.

Working Mechanism

Impeller Rotation: The impeller's rotation drives the slurry to flow, ensuring that mineral grains and reagents are thoroughly mixed.

Radial Circulation: The flat-bottomed, barrel-shaped design with a radial circulation spiral impeller ensures efficient mechanical stirring.

Optimal Mixing: The mechanical stirring type ensures that the reagents are fully mixed with the ore pulp, enhancing the reaction quality and efficiency.

The agitator tank is crucial for preparing ore pulp by thoroughly mixing it with reagents before flotation. Its design is suitable for various metal and non-metal ores, operating efficiently at specific concentrations and particle sizes. This high-efficiency agitation tank is widely used in mining, chemical, construction, cyanide chemical plants, sewage treatment, and coal plants, ensuring thorough mixing and preparation of slurries for various processes.

*The output will vary according to different materials, feed particle size and other factors