Terbaikmachinery offers efficient dry ball mills designed for precise grinding in mineral processing operations. Our ball milling equipment ensures consistent performance and optimal particle size reduction, enhancing material pulverization and ore grinding processes. Trust Terbaikmachinery for expertly crafted grinding solutions that deliver superior results and maximize productivity.

The ball mill is a versatile and efficient grinding machine widely used in various industries, including construction, electricity, coal, and metal ore processing. This article highlights its applications, operational features, and key benefits.

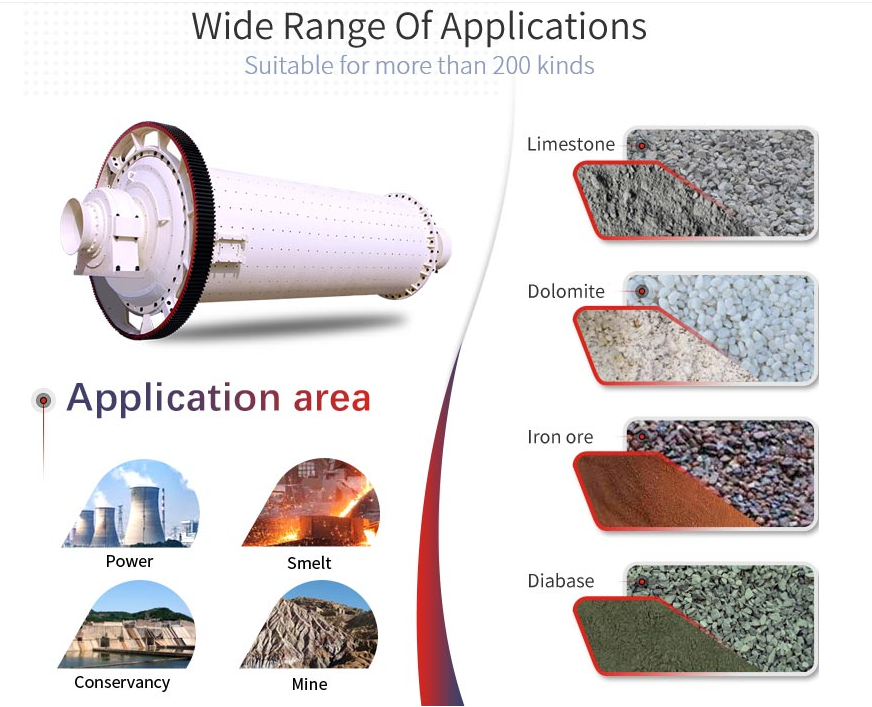

Applications:

Ball mills are ideal for grinding materials down to fine powders, particularly in the following sectors:

Construction: For grinding raw materials used in the manufacture of building materials.

Electricity: In the production of materials for energy-related applications.

Coal: For pulverizing coal for power generation.

Metal Ore: For processing metallic ores and non-metallic minerals.

Cement: For grinding cement raw materials and additives.

Building Material Industry: To grind materials such as cement, limestone, and clay.

Chemical Industry: For the production of chemicals and other materials.

Mining: To grind metallic and non-metallic ores.

Applied Materials:

Ball mills are utilized for grinding a diverse range of materials, including:

Minerals: Steel slag, white ash, gold ore, iron ore, zinc ore, copper ore, molybdenite, quartz, bauxite, manganese, tungsten.

Building Materials: Marble, granite, bluestone, kaolin.

Chemical Inputs: Mica, calcite, fluorite, magnesite, aluminum powder, aluminum powder paste.

Others: Hematite, iron concentrate, barite, potash feldspar, tungsten carbide, clinker, slag, and more.

The ball mill is a crucial piece of equipment for efficiently grinding various materials in multiple industries. With its ability to achieve fine particle sizes, high capacity, and energy-efficient operation, it remains a popular choice for material processing and production.

1. Durable Liner Material: The liner of the dry ball mill is constructed from high-quality, wear-resistant materials. This ensures enhanced strength, durability, and an extended service life, reducing the need for frequent replacements.

2. Adjustable Product Fineness: The mill offers adjustable fineness levels, allowing for precise control over the particle size of the final product. This ensures a uniform and high-quality output that meets specific processing requirements.

3. Large Capacity and Crushing Ratio: The dry ball mill is designed to handle large volumes of material, providing a high crushing ratio. Its efficient sealing performance makes it adaptable to various working conditions, improving overall operational flexibility.

4. High Grinding Efficiency: With its advanced design, the dry ball mill achieves high grinding efficiency, which translates to better performance and reduced operational costs. It operates with lower energy consumption compared to traditional milling equipment, making it a cost-effective choice for processing materials.

These features collectively make the dry ball mill a versatile and efficient tool for various industrial applications, ensuring reliable performance and high-quality results.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The dry ball mill is a crucial piece of equipment used in various industries for grinding materials. Its operation involves the following key principles:

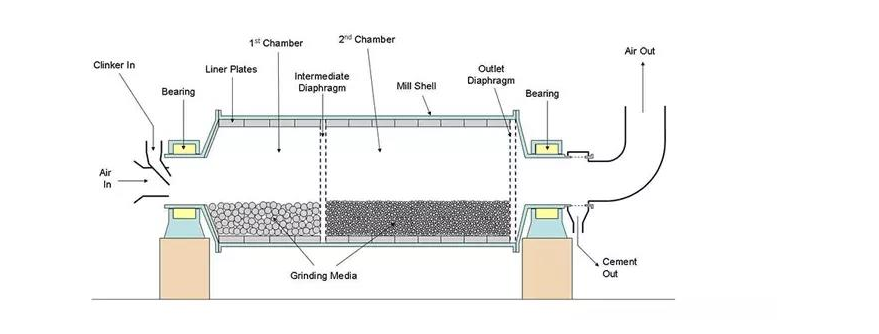

1. Structure and Rotation:

Horizontal Cylinder: The ball mill features a horizontal cylindrical drum that rotates around its axis. It is driven by outer gears, ensuring smooth operation.

Chamber Design: The mill consists of two main chambers. The first chamber is equipped with ladder liners or ripple liners and filled with steel balls of different sizes.

2. Material Transfer and Grinding:

Material Feeding: Materials are introduced into the mill through the quill shaft, which evenly distributes them into the grinding chamber.

Grinding Mechanism: As the cylinder rotates, centrifugal force causes the steel balls to rise to a certain height. These balls then fall freely, impacting and grinding the materials within the chamber. This repeated impact and friction effectively reduce the size of the materials.

3. Rotation Speed:

Operational Speed: The rotation speed of the mill typically ranges from 4 to 20 revolutions per minute (RPM), depending on the mill's diameter. Larger mills generally operate at slower speeds.

Critical Speed: If the mill's speed exceeds a certain threshold known as the "critical speed," it behaves like a centrifuge. In this state, the balls remain on the mill's walls and do not fall, leading to ineffective grinding. Ball mills generally operate at 65 to 75 percent of this critical speed to maintain optimal grinding efficiency.

4. Grinding Chambers:

First Chamber: This chamber contains step or corrugated liners and a mix of steel balls. It is responsible for the initial coarse grinding of materials.

Second Chamber: After coarse grinding, the material passes through a single-layer partition into the second chamber. This chamber, lined with flat liners and additional steel balls, further refines the material.

5. Discharge:

Final Product: The finely ground material is discharged through an unloading grate, completing the grinding process.

6. Safety and Trial Operation:

Initial Testing: Once installed and inspected, the ball mill undergoes a trial operation without load. This test is performed by skilled operators who must adhere to strict safety protocols to ensure the mill operates correctly and safely.

In summary, the ball mill uses centrifugal force generated by its rotation to grind materials effectively. Its design, operational parameters, and safety measures are crucial for achieving efficient and reliable performance in various industrial applications.

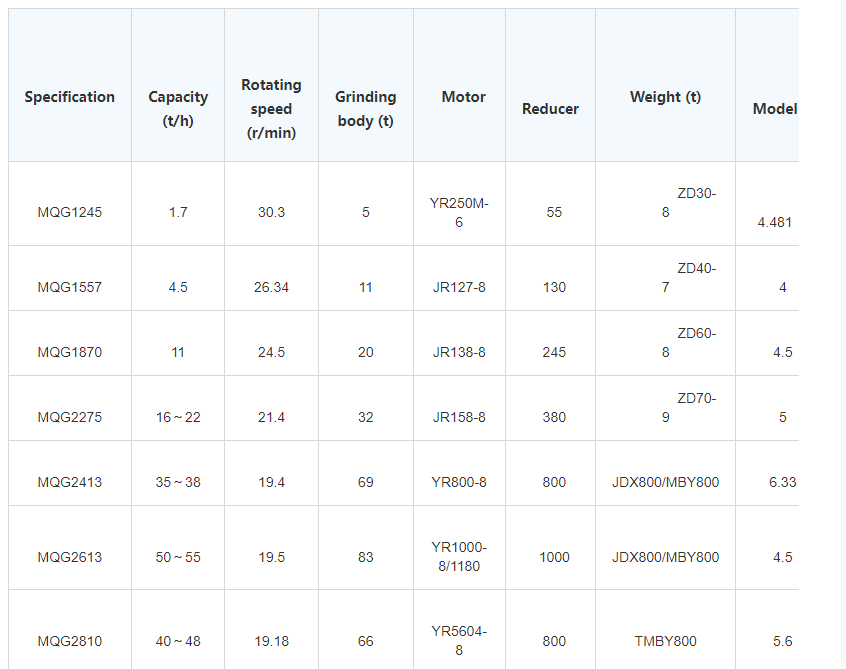

*The output will vary according to different materials, feed particle size and other factors