Low Price Mining Reversible Hammer Crusher

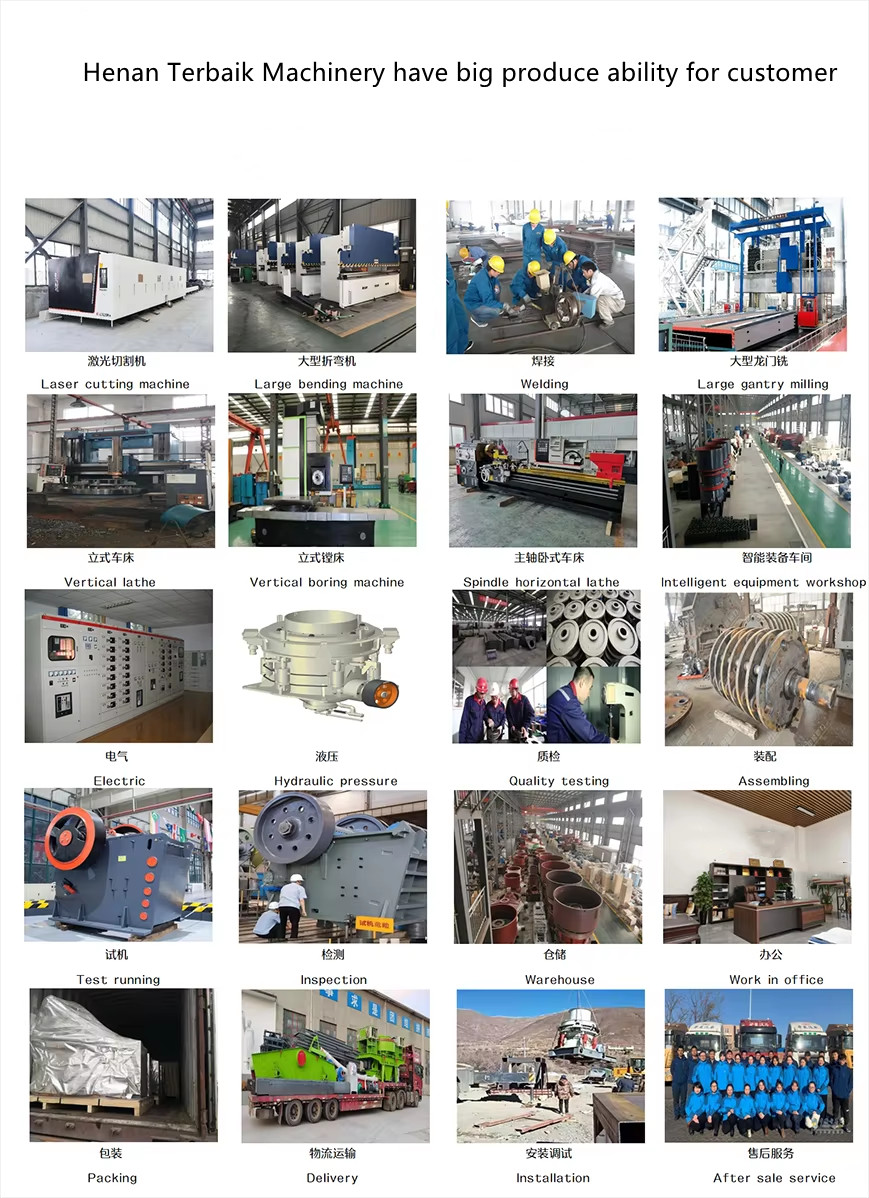

Terbaikmachinery offers High Efficient Fine Crushers for superior crushing solutions in various industries. Our fine crushers ensure efficient material pulverization, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted crushing solutions that deliver superior results and optimize your mining material processing operations.

- 210mm--1020mmInput Size

- Primary CrusherType

- 3-500t/hCapacity

Application of High Efficient Fine Crusher

What is a Reversible hammer crusher ?

The reversible hammer crusher is named after the rotor can rotate in both directions. It is one of the crushing equipment for crushing limestone, coal, or other brittle materials below medium hardness in metallurgy, building materials, the chemical industry, hydropower, and other industrial fields.

Application of reversible hammer crusher

Reversible hammer crusher is an efficient, reliable and adaptable crushing equipment that can meet the needs of various industrial sectors for fine crushing of materials. It is widely used in industrial sectors such as metallurgy, building materials, chemical industry and hydropower for fine crushing of brittle materials with medium hardness or below, such as limestone, coal, gypsum and soft refractory materials.

Advantages of High Efficient Fine Crusher

Main features of a reversible hammer crusher

1. Large crushing ratio: The crushing ratio of reversible hammer crusher can reach up to 20, which can effectively crush the material to the required particle size.

2. High production capacity: The equipment has efficient production capacity and can meet the needs of large-scale production.

3. Uniform product particle size: The material particle size after crushing by a reversible hammer crusher is uniform and meets production requirements.

4. Advanced structure: Reversible hammer crusher adopts advanced product structure, reliable performance, stable operation and low energy consumption.

5. Reversible crushing: The hammer head uses two sides, and the life span is increased by more than 1 times, which reduces the production cost.

6. Mechanical gap adjustment: It can compensate for the increase of particles caused by wear of wearing parts and maintain the stable operation of the equipment.

7. Impact plate heating system: It can be used to process wet and sticky materials so that drying and crushing can be carried out at the same time, which improves the adaptability of the equipment.

-

High Quality

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

-

Customized Design

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

-

Good Performance

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

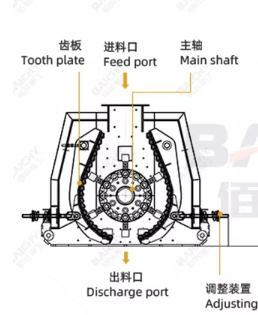

Working principle

The working principle of the reversible hammer crusher is mainly to crush materials by impact.

1. After entering the crusher, it is crushed by the impact of the high-speed rotating hammer.

2. The crushed material obtains kinetic energy from the hammer and rushes to the baffle and screen bar in the frame at high speed. At the same time, the materials collide with each other and are crushed multiple times.

3. The material smaller than the gap between the screen bars is discharged from the gap. Some larger materials are crushed again on the screen bar by the impact, grinding and extrusion of the hammer until the product of the required particle size is obtained.

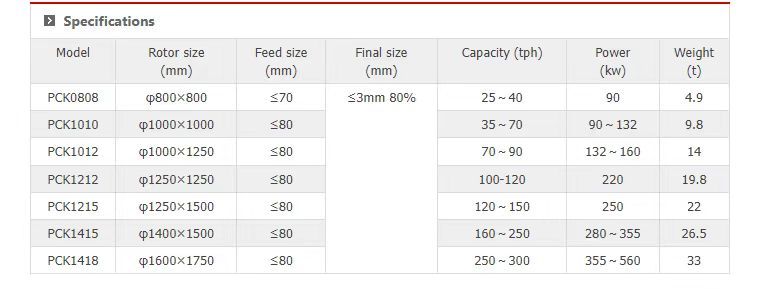

Specification

Composition of reversible hammer crusher

Reversible hammer crusher is mainly composed of frame, rotor, screen bar, impact plate, adjustment device, etc. The rotor is the core component of reversible hammer crusher. Its reversibility enables the hammer head to be used on both sides, which prolongs the service life of the hammer head.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors

-

Whatsapp

+86-19139706301

+86-19139706301

-

Wechat

+86-19139706301

+86-19139706301

-

EmailKevin@terbaikmachinery.com

- Back