Terbaikmachinery offers efficient batch ball mills designed for precise grinding in mineral processing operations. Our ball milling equipment ensures consistent performance and optimal particle size reduction, enhancing material pulverization and ore grinding processes. Trust Terbaikmachinery for expertly crafted grinding solutions that deliver superior results and maximize productivity.

The ceramic ball mill is mainly used for the mixing and grinding of materials, the fineness of the product is uniform, and the power is saved. Both dry and wet grinding can be used. The machine can adopt different liner types according to production needs to meet different needs. The fineness of the grinding operation is controlled by the grinding time. The electric machine is started by self-coupling decompression to reduce the starting current. Its structure is divided into integral type and independent type.

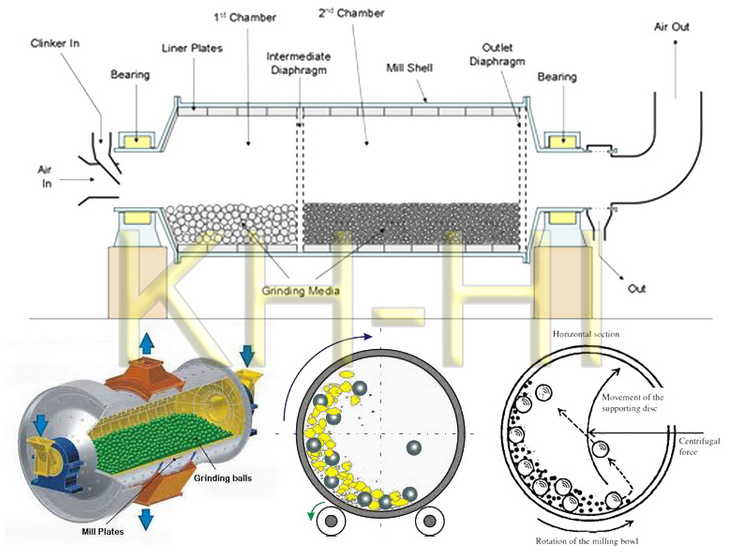

Grinding Operation:

The grinding process within the silica stone lined batch ball mill involves a horizontal cylindrical drum that rotates. As the drum rotates, the material and grinding balls are lifted to a certain height by centrifugal force.

Grinding Mechanism: The steel balls in the mill experience two primary forces:

Tangential Force: Applied during rotation, causing the balls to move along the cylinder's surface.

Gravitational Force: Due to the ball’s own weight, causing it to fall from the top of the cylinder to the bottom.

These forces create a pair of force couples that induce friction between the balls and between the balls and the cylinder. As the balls fall and collide with the material, they generate a combination of peeling, impact, and squeezing forces that effectively crush and grind the material.

The silica stone lined batch ball mill is an efficient and versatile grinding tool, particularly well-suited for industries where precise material processing is critical.

Application:

Ceramic ball mills are widely used in the grinding of electronic materials, magnetic materials, ceramic glaze slurry, ink pigments, non-metallic minerals, glass, pigments, coatings, electromagnetics, refractory materials and other materials.

It can also be used for the grinding of chalk, gypsum, bricks, limestone , feldspar, silica, quartz, ceramics, clay, glass, rubber, plastics, etc.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The silica stone lined batch ball mill is designed for the fine grinding of various materials in a batch mode. It is particularly effective for materials like silica stone, where the lining material helps to enhance the grinding process.

1. Rotation and Grinding:

The operation of the batch ball mill begins when the motor drives the cylinder drum to rotate. The drum’s rotation is facilitated by an outer gear transmission system.

Raw material is introduced into the cylinder through one end. Inside the drum, grinding balls are present, which rotate along with the cylinder.

2. Impact and Grinding:

As the drum rotates, the grinding balls are lifted to a certain height by centrifugal force. When the balls fall back down, they impact and grind the material repeatedly.

The continuous impact and grinding action of the balls on the material lead to size reduction.

3. Material Handling:

The grinding action within the drum results in the accumulation of milled materials.

Once the grinding process is complete, the ground material is discharged from the end outlet of the mill.

4. Bin Structure:

The batch ball mill features a horizontal cylindrical design with two separate compartments or bins.

First Bin: The material enters the first bin through a feeding hollow shaft spirally. This bin is lined with step liners or corrugated liners and contains steel balls of varying specifications. The rotation of the cylinder in this compartment causes centrifugal force to lift the steel balls, which then fall and exert heavy blows on the material, causing initial grinding.

Second Bin: After the material undergoes preliminary grinding in the first bin, it passes through a single-layer partition board into the second bin. This compartment is lined with flat liners and contains additional steel balls to further grind the material.

5. Discharge and Operation Completion:

The finely ground material exits the mill through an unloading grate plate, completing the grinding operation.

The silica stone lined batch ball mill operates efficiently by combining rotation, centrifugal force, and the repeated impact of grinding balls. This setup ensures thorough grinding of materials, with a two-bin structure optimizing the grinding process and improving the overall efficiency of the operation.

The ball mill can process barite, coal slime, potassium feldspar, tungsten carbide, copper ore, slag, hematite, white ash, gold ore, aluminum powder, high alumina porcelain, iron powder, fluorite ore, aluminum powder paste, Steel slag, quartz sand, sulfuric acid slag, barite, clinker, bauxite, ceramsite sand, etc. dozens or even hundreds of ores.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

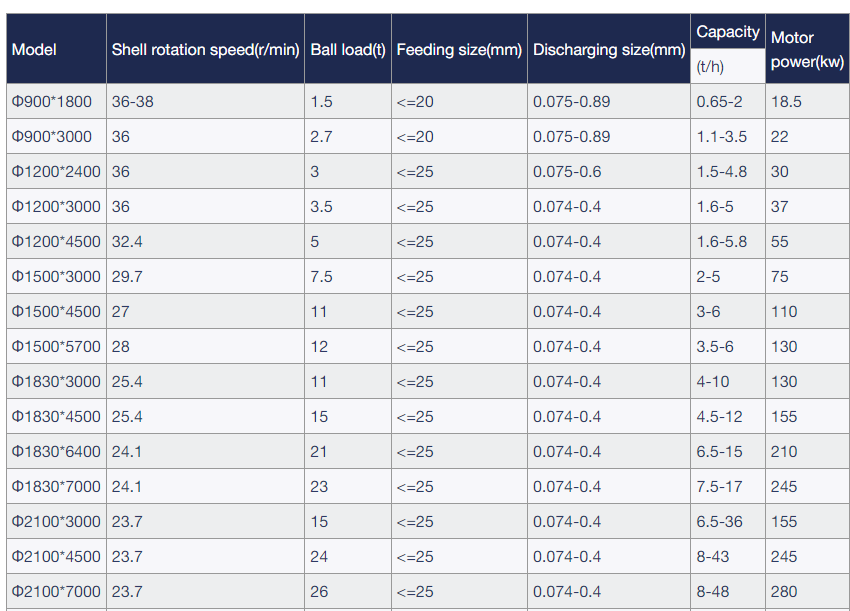

*The output will vary according to different materials, feed particle size and other factors