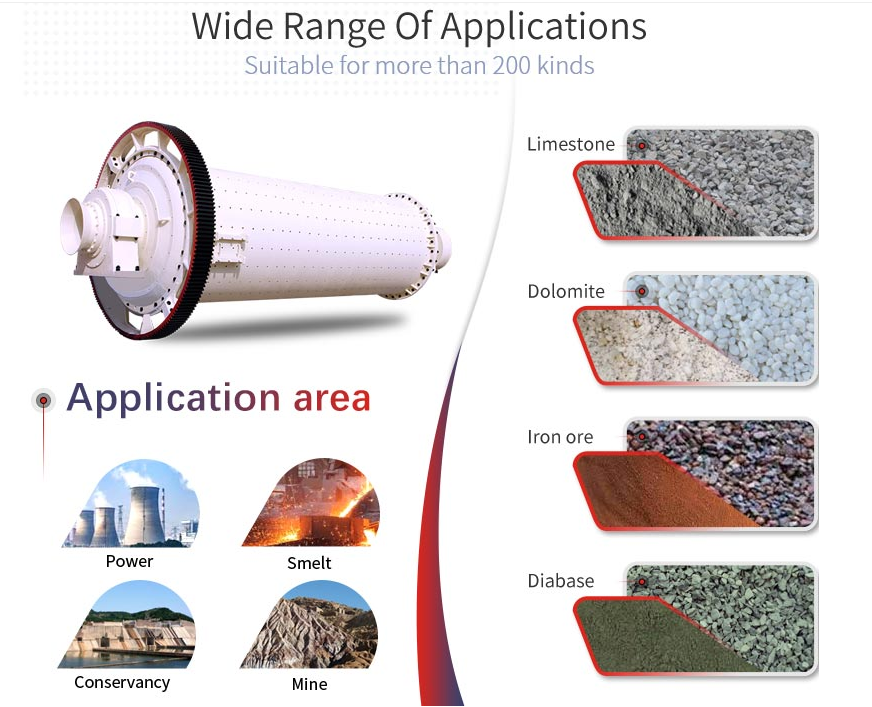

Terbaikmachinery offers Ball Mills for versatile grinding solutions in various industries. Our Ball Mills ensure precise material pulverization, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted grinding solutions that deliver superior results and optimize your material processing operations.

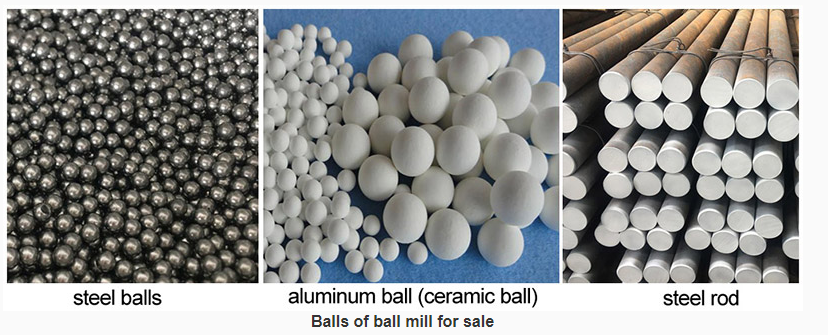

Ball mill grinding equipment is an important machine widely used in many industries, mainly used for crushing and grinding materials. Its core part is a horizontal cylinder with grinding bodies (such as steel balls) inside. When the cylinder rotates, the grinding bodies collide and rub with the materials under the action of inertia and centrifugal force, thereby grinding the materials.

According to the grinding method, ball mills can be divided into dry and wet types; according to the discharge method, they can be divided into grid type and overflow type; according to the shape of the cylinder, they can be divided into short-cylinder ball mills, long-cylinder ball mills, tube mills, and cone mills.

Based on discharge methods can be divide into 3 models overflow type ball mill , grate (or grid ) type ball mill , and peripheral type (this type most is rod mill )

Grate type ball mill

The grate type ball mill is a low-level forced ore discharge machine, which stores less slurry in the grinding machine. so, higher density minerals are not easily concentrated in the grinding machine.

Overcrushing is lighter than overflow type ball mills

The grinding speed can be faster.

The productivity of grate type is usually 10% to 20% higher than overflow type.

Overflow type ball mil

Overflow type ball mill has a simple structure

Easy to manage and maintain.

It is better for fine grinding than grate type,

Overflow type ball mills are often used in mineral processing.

High grinding efficiency: Especially suitable for grinding materials with high hardness and high viscosity, the product fineness can reach the submicron level.

Wide range of use: Can be used to grind a variety of materials, such as magnetic materials, inorganic non-metallic materials, organic chemical materials, etc.

Simple maintenance: Simple structure, easy to use, only need to pay attention to the addition of materials and daily maintenance of equipment.

High precision: Can achieve fine grinding of materials, and high precision of the grinding process.

1)Discharging size > 0.2mm , usually by grate type ball mill or over flow type ball mill;

2)Discharging size < 0.2mm, usually by over flow type ball mill;

3)2-stage grinding

First stage usually by grate type or over flow type

Second stage usually by over flow type.

1)Discharging size P80 (200mesh < 65% , check mesh to mm converter ), usually use one stage ball mill grindingP80=106~75um(200mesh is 65% - 80%) , by two stage.

3)Discharging size P80=75~55um(200mesh is 80% - 90%), by three stage

3)Discharging size P80<55μm(200mesh is> 90%),by three stage

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

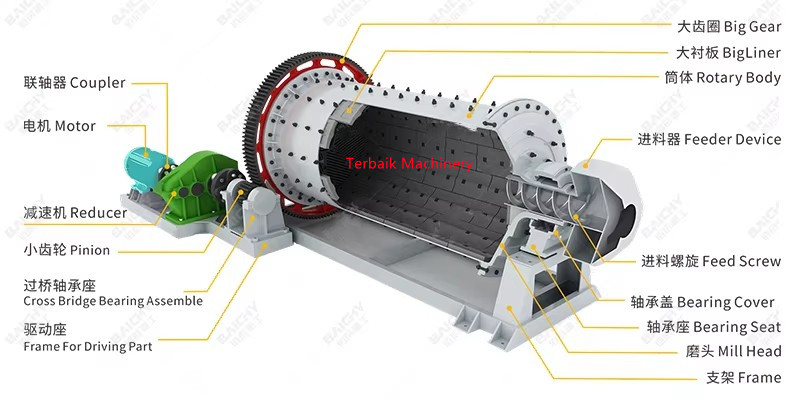

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different specifications.Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it will give a heavy blow to materials, playing a role of grinding. Materials after crushed in the first bin shall enter bin across single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding. The ground materials are discharged through the discharging board thus the grinding process is finished.

1.How to choose the model of the ball mill?

Answer:

1)first confirm your material, wet type ball mill or dry type ball mill?

2)second confirm your capacity?

the capacity has term of hadness of the material.

usually MQG/MQY900x1800 0.5 - 2 ton per hour

MQG/MQY1200x2400 1 - 3ton per hour

MQG/MQY1500x3000 2 - 5ton per hour

they also have model 1830x3000,2100x4500,2200x4500 etc.

2.Does the ball mill can be driven by diesel engine?

Answer: yes, the ball mill can be driven by motor or diesel,especially the small ball mill.

3.Test run requirement of the new ball mill

A.Continuous idle working time no less than 12-24 hours, solving the problems in time when it happens.

B.After the idle run, can make the on load test run, feeding proper ore into the ball mill, mind to avoid the damage of ball and steel plate.

Steps:

1、Add proper ore and 1/3 ball, working 12-24 hours.

2、Add 2/3 balls working 24-48 hours

3、According to the discharging situation, the capacity of good products, to assure the suitable ball load quantity of ball mill, then working no less than 72 hours.

Model | Shell | Ball | Feeding | Discharging | Capacity (t/h) | Motor | Weight(t) |

Φ900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

Φ900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Φ1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

Φ1200*3000 | 36 | 3.5 | <=25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Φ1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Φ1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Φ1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 110 | 21 |

Φ1500*5700 | 28 | 12 | <=25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Φ1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

Φ1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 |

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors