Explore our mobile impact crushers. Discover mobile impact crushing equipment designed for maximum efficiency and mobility. Learn about the specifications, benefits, and applications of our mobile crushers. Choose the best mobile impact crusher for your needs.

Mobile impact crushers are track-mounted or wheel-mounted rock crushing machines designed for easy mobility on and between production sites. They are extensively used in aggregate production, recycling applications, and mining operations. These crushers can replace stationary crushing systems, thereby reducing the need for material hauling and cutting operational costs.

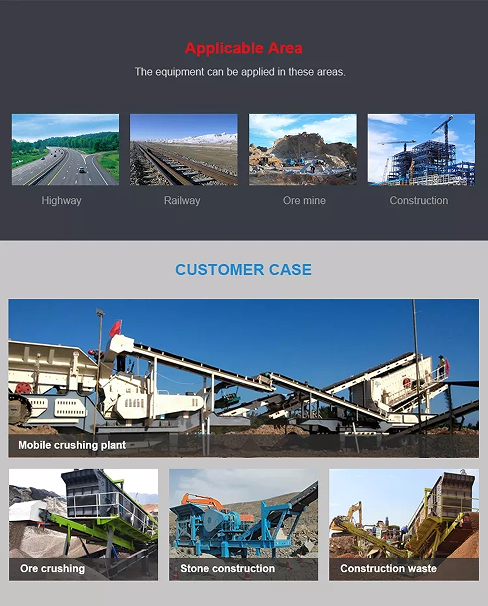

The mobile impact crusher plant is a versatile and powerful piece of equipment designed for a variety of crushing needs across multiple industries. Its mobility and efficiency make it an ideal choice for several applications.

1. Quarrying and Mining

Secondary and Tertiary Crushing: Ideal for secondary and tertiary crushing of various minerals and rocks, the mobile impact crusher plant can process materials like limestone, granite, basalt, and more.

Versatility: Capable of handling different types of materials, from hard rock to softer aggregates, providing high crushing efficiency and product quality.

2. Road and Railway Construction

Aggregate Production: Produces high-quality aggregates used in road base, asphalt, and concrete, essential for road and railway construction projects.

Remote Area Operations: Its mobile nature allows it to operate in remote or difficult-to-access areas, ensuring a continuous supply of materials for construction projects.

3. Industrial Applications

Material Processing: Suitable for processing various industrial materials, including slag, coal, and other minerals, ensuring efficient handling and crushing.

Customizable Solutions: The mobile impact crusher plant can be configured to meet specific industrial crushing requirements, providing tailored solutions for different material processing needs.

4. Aggregate Production

Crushing and Screening: The mobile impact crusher plant can be used for both crushing and screening purposes, producing various sizes of aggregates required for different applications.

Portable Solutions: Provides a flexible and portable solution for aggregate production, meeting the demands of both large-scale and small-scale projects.

The mobile impact crusher plant's versatility and efficiency make it an essential tool across multiple industries. Its ability to provide high-quality crushing solutions while maintaining mobility and flexibility ensures it meets the demands of modern construction, mining, recycling, and industrial projects. By choosing a mobile impact crusher plant, businesses can benefit from improved productivity, cost savings, and environmentally friendly operations.

Our mobile crushing plant, portable crushing plant is mainly used for coarse crushing and fine crushing. All the crushing and screening machines are erected on the truck , it can quickly move to job site, and easily setup to handle different products. This portable stone crusher provides a new field of business opportunities for, quarry operators, recycling, mining ore crushing and construction waste crushing. It offers high efficient and low cost project plan without environment limit for the clients.

High Flexibility

The mobile impact crushing station features an integrated design that allows easy relocation to different work sites without complex installation or dismantling processes. This flexibility enables efficient handling of materials like construction waste, rocks, and minerals, swiftly adapting to diverse work environments.

Efficient Crushing Capacity

Operating on the principle of impact crushing, the impact crusher efficiently crushes materials to produce well-sized finished products. It boasts a high crushing ratio and efficiency, satisfying varying user requirements for material particle size.

Strong Adaptability

Capable of processing numerous materials, including medium-hardness and brittle substances like limestone, gypsum, and coal, the mobile impact crushing plant proves versatile across various industries and applications.

Cost Saving

Direct site-to-site mobility for crushing operations eliminates the need for material transportation, thus reducing associated costs. Additionally, its integrated design minimizes equipment footprint and infrastructure requirements, contributing to overall investment savings.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Mobile crusher has the features of reasonable matching of all levels of crushing equipment; smooth discharging of the whole production line, reliable running condition, convenient operation and high efficiency and energy conservancy. It has good mobility and can extend together with the raw materials site or construction site and has many types of combinations to satisfy the processing needs of different materials.

First, raw materials (such as ores, rocks, construction waste, etc.) are fed into the silo of the mobile impact crushing station using forklifts, excavators, and other equipment. These raw materials then enter the screening feeder. Smaller materials pass directly through the screen holes, forming mounds or being further processed by the excavating belt conveyor.

Larger materials continue into the impact crusher via the screening feeder. Inside the impact crusher, the motor drives the rotor to rotate at high speed through a triangle belt. The plate hammer on the rotor radiates outward under the influence of centrifugal force. When the material enters the plate hammer's rotating range, it is struck by the high-speed rotating hammer. The material is then flung towards the impact plate along the tangential direction of the hammer. This impact process causes the material to be continuously impacted and compressed in the crushing cavity, leading to the breakdown of its internal structure and ultimately achieving crushing.

*The output will vary according to different materials, feed particle size and other factors