Enhancing Aggregate Production with Advanced Crushing & Screening Technology

Henan Terbaikmachinery, a leading manufacturer of mining crushing and screening equipment, has successfully installed a 200-300TPH river stone separator plant in Tagum City, Davao, Philippines. This cutting-edge plant is designed to maximize efficiency in processing river sand while ensuring high-quality aggregates for construction and infrastructure projects.

The increasing demand for premium aggregates in the Philippines’ booming construction sector has made it essential for companies to invest in high-performance crushing and screening equipment. Henan Terbaikmachinery's latest river stone separator plant in Tagum City stands out due to its advanced vibrating screen technology, high processing capacity, and cost-efficient operation.

.jpg)

Optimized Configuration for Maximum Output

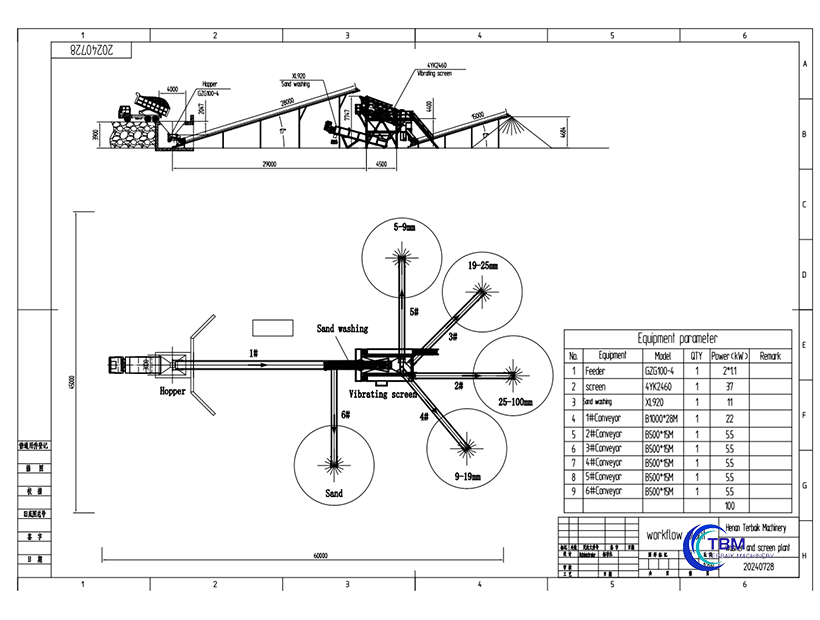

The 200-300TPH river stone separator plant is built with a robust and efficient design to handle a variety of river sand and stone processing requirements. It is equipped with the latest technology to ensure consistent particle size distribution, reduce material loss, and improve overall productivity.

Detailed Equipment Configuration:

✔ 4x3x3 Hopper – Large-capacity material storage for continuous feeding

✔ GZG1224 Vibrating Feeder – Ensures a steady and controlled material flow to prevent blockages

✔ B800x28m Conveyor Belt – Transfers materials efficiently, minimizing downtime

✔ 4YK2460 Vibrating Screen – High-precision screening technology for effective material separation

✔ XL920 Spiral Washer – Advanced washing system to remove impurities from river sand

✔ Four B650x15m Conveyor Belts – Optimized for smooth material transportation

Material Specifications & Processing Capacity

✔ Material Processed: River Sand

✔ Maximum Feeding Size: 100mm

✔ Final Product Sizes: 0-5mm, 5-9mm, 9-19mm, 19-38mm

✔ Processing Capacity: 200-350TPH

.jpg)

Key Advantages of the 200-300TPH River Stone Separator Plant

✅ High-Efficiency Aggregate Processing

This plant is specifically designed for handling large volumes of river stones while maintaining high precision in particle size separation.

✅ High-Quality End Products

With a multi-stage screening process, the plant produces well-graded aggregates suitable for road construction, concrete production, and other infrastructure applications.

✅ Cost-Effective & Energy-Efficient Operation

By utilizing advanced vibrating screen technology and low-energy washing systems, the plant reduces power consumption while maximizing output efficiency.

✅ Environmentally Friendly Processing

The XL920 Spiral Washer ensures minimal water wastage, contributing to sustainable production practices in the Philippines’ aggregate industry.

✅ Durability & Low Maintenance Costs

All components of the plant are built with wear-resistant materials, ensuring longer service life and reduced maintenance costs.

Why Choose Henan Terbaikmachinery?

As a globally recognized manufacturer of crushing, screening, and sand washing equipment, Henan Terbaikmachinery provides customized solutions tailored to meet the specific needs of clients in Southeast Asia, Africa, and beyond.

With years of experience in mining and construction machinery, the company focuses on:

Single cylinder hydraulic cone crusher