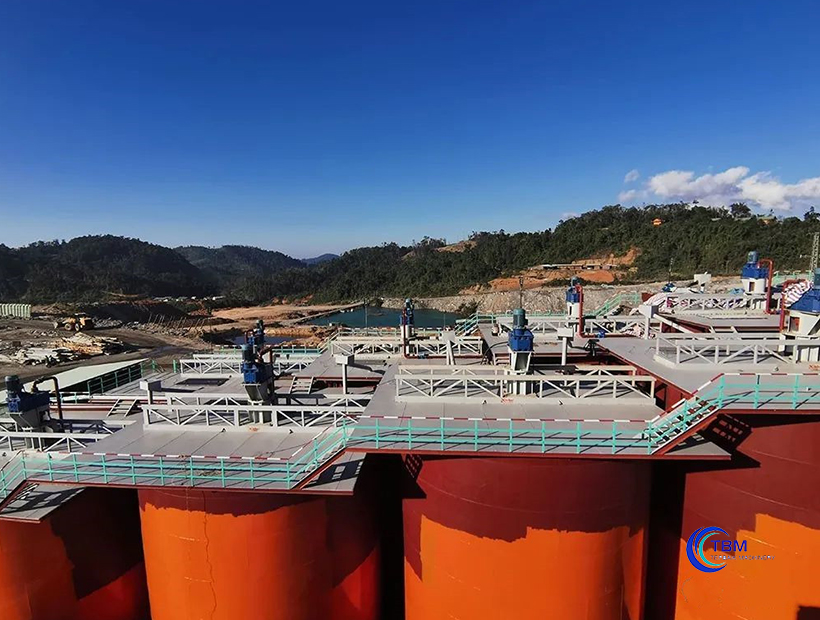

In the mining industry, gold extraction is a crucial process that involves separating gold from ore using various techniques. One of the most widely used methods is gold leaching, a process that uses chemical solutions to dissolve gold from its ore. The gold leaching tank plays an essential role in this process, providing an efficient environment for gold extraction. Henan Terbaikmachinery, known for its mining equipment, offers high-quality gold leaching tanks designed to enhance gold recovery rates and optimize the leaching process for mining operations in Southeast Asia and Africa.

What Is the Process of Gold Tank Leaching?

The process of gold tank leaching involves several stages that allow gold to be extracted from the ore. The primary method of gold leaching is cyanidation, which uses cyanide solutions to dissolve the gold from crushed ore. Here is a brief overview of the gold leaching process:

Ore Preparation: Gold ore is first crushed and ground to a fine particle size to increase the surface area for effective leaching.

Leaching Solution: The crushed ore is mixed with a cyanide solution in a gold leaching tank. The cyanide reacts with the gold, dissolving it into the solution.

Gold Recovery: The gold-laden solution is then separated from the remaining solids and processed to recover the gold, often using activated carbon or other recovery techniques.

Refining: The gold solution is further refined to extract pure gold, which can then be processed into bullion.

The gold leaching tank size is an important factor in this process, as it must accommodate the volume of slurry and allow the cyanide solution to properly interact with the gold-bearing ore.

How Much Does Gold Heap Leaching Cost?

Gold heap leaching is another form of gold extraction that is typically used for low-grade ores. In this method, crushed ore is piled onto large pads and irrigated with a cyanide solution. The solution percolates through the heap and leaches gold from the ore over time.

The cost of gold heap leaching depends on several factors, including the size of the heap, the amount of cyanide solution required, and the overall efficiency of the process. Gold heap leaching costs can vary significantly, but it is generally less expensive than traditional gold extraction methods, making it suitable for large-scale operations. The gold leaching tank price and the cost of the cyanide solution are also important considerations for mining companies when choosing between heap leaching and tank leaching methods.

How Do You Leach Gold Without Cyanide?

Although cyanide is the most common chemical used in gold leaching, non-cyanide gold leaching methods are being explored as safer and more environmentally friendly alternatives. Some of the popular alternatives include:

Thiosulfate Leaching: This process uses thiosulfate as a leaching agent, which is less toxic than cyanide and works well in certain types of ore.

Chlorine Leaching: Chlorine-based solutions can be used to dissolve gold from ore, although this method is less commonly used in comparison to cyanidation.

Bioleaching: Certain bacteria can be used to leach gold from ore by producing organic acids that dissolve the gold.

While these methods are being explored for their environmental benefits, cyanide-free gold leaching methods are not yet as widely implemented in commercial operations due to their higher costs and slower leaching rates.

What Temperature Is Gold Leaching?

The temperature at which gold leaching occurs plays a significant role in the efficiency of the process. Typically, the leaching process is carried out at temperatures ranging from 20°C to 60°C. Warmer temperatures generally accelerate the leaching reaction, leading to faster gold recovery. However, higher temperatures can also increase the rate of cyanide consumption, which can be costly. Therefore, it is important to balance temperature and efficiency when designing the leaching process.

In a gold leaching tank, maintaining the ideal temperature is crucial for optimizing the leaching process and ensuring that the maximum amount of gold is extracted from the ore.

Conclusion

Gold leaching is a complex and highly specialized process that plays a crucial role in extracting valuable gold from ore. The gold leaching tank is central to this process, ensuring that the ore is efficiently treated and gold is recovered. Henan Terbaikmachinery offers a range of gold leaching tanks for sale, designed to meet the specific needs of mining operations. With efficient leaching tank design and optimal tank size, Henan Terbaikmachinery’s tanks provide cost-effective and reliable solutions for gold recovery.

For more information about the gold leaching process, gold leaching tank price, and to inquire about purchasing a gold leaching tank, feel free to contact Henan Terbaikmachinery. We are here to help you optimize your gold extraction operations.