Introduction to Gold Ore Processing Plants

Gold ore processing plants are vital in the mining and extraction industry, playing a crucial role in refining raw gold ores into high-purity gold. These plants employ a series of complex processes to ensure maximum extraction and recovery of gold from the ore, enhancing the overall yield and profitability of mining operations. This article delves into the key aspects of gold ore processing plants, focusing on their operation, technology, and benefits for the Southeast Asian market, provided by Terbaikmachinery.

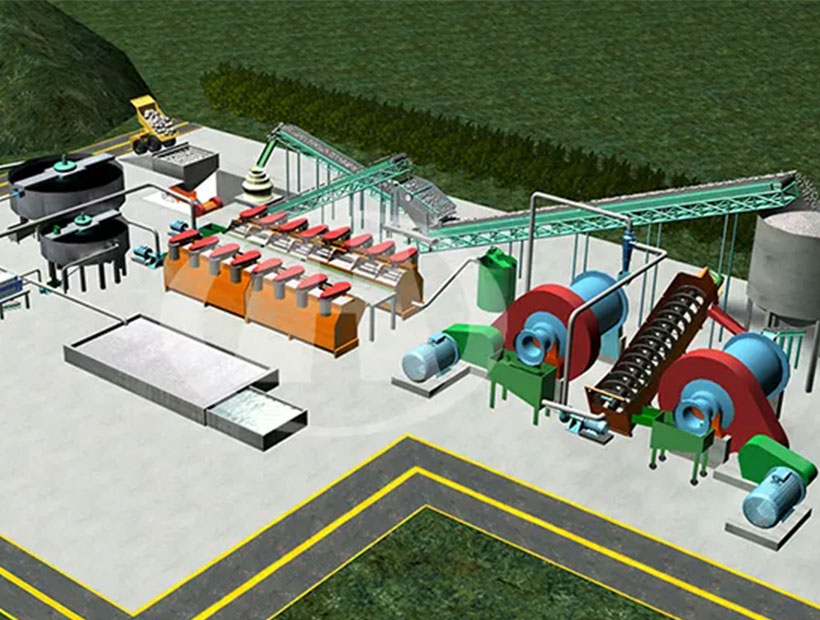

What is a Gold Ore Processing Plant?

A gold ore processing plant is a facility designed to extract and refine gold from mined ores. These plants utilize a variety of equipment and techniques to separate gold from other minerals and impurities in the ore. The primary goal is to achieve the highest possible gold yield while minimizing environmental impact and operational costs.

Key Components of a Gold Ore Processing Plant

-

Crushing and Grinding: The initial stage of gold ore processing involves crushing and grinding the ore to reduce its size and liberate the gold particles. This is typically done using jaw crushers, cone crushers, and ball mills.

-

Screening and Classification: The crushed ore is then screened and classified to separate fine particles from coarse ones. This step ensures that only the particles suitable for further processing move forward.

-

Gravity Separation: Gravity separation methods, such as jigging and shaking tables, are used to concentrate gold by exploiting differences in density between gold and other minerals.

-

Flotation: Flotation is a widely used method for separating gold from sulfide ores. In this process, chemicals are added to a slurry of finely ground ore, causing the gold to attach to air bubbles and rise to the surface for collection.

-

Cyanidation: Cyanidation, or leaching, is the most common method for extracting gold from ore. In this process, cyanide solution is used to dissolve gold, which is then recovered from the solution using activated carbon or zinc precipitation.

-

Electrowinning and Smelting: The final stage involves electrowinning to recover gold from the leach solution, followed by smelting to produce high-purity gold bars.

Advanced Techniques in Gold Ore Processing

Modern gold ore processing plants incorporate advanced technologies to enhance efficiency and recovery rates. Some of these techniques include:

-

Automated Control Systems: Advanced control systems are used to monitor and optimize the various stages of processing, ensuring consistent performance and reducing human error.

-

High-Efficiency Equipment: Newer equipment designs, such as high-pressure grinding rolls (HPGR) and ultra-fine grinding mills, improve the efficiency of crushing and grinding, leading to higher gold recovery rates.

-

Eco-Friendly Solutions: Innovations in environmentally friendly processing methods, such as bio-oxidation and thiosulfate leaching, minimize the environmental impact of gold extraction.

Benefits of Modern Gold Ore Processing Plants

-

Higher Recovery Rates: Advanced processing techniques and equipment lead to higher gold recovery rates, maximizing the yield from each ton of ore.

-

Lower Operational Costs: Improved efficiency and automation reduce the cost of operations, making gold mining more profitable.

-

Environmental Sustainability: Eco-friendly processing methods help reduce the environmental footprint of gold mining, aligning with global sustainability goals.

-

Increased Throughput: Modern processing plants are designed to handle larger volumes of ore, increasing the overall productivity of mining operations.

Conclusion

Gold ore processing plants are essential for transforming raw gold ores into valuable, high-purity gold. By incorporating advanced technologies and efficient processing methods, these plants ensure maximum recovery rates and operational efficiency. As the industry continues to evolve, the adoption of modern, environmentally sustainable practices will play a crucial role in the future of gold mining, particularly in the dynamic and resource-rich Southeast Asian market.

At Terbaikmachinery, we are committed to providing high-quality gold ore processing plants and innovative mineral processing solutions tailored to meet the specific needs of the Southeast Asian market. For more information or inquiries about our products, please contact us: